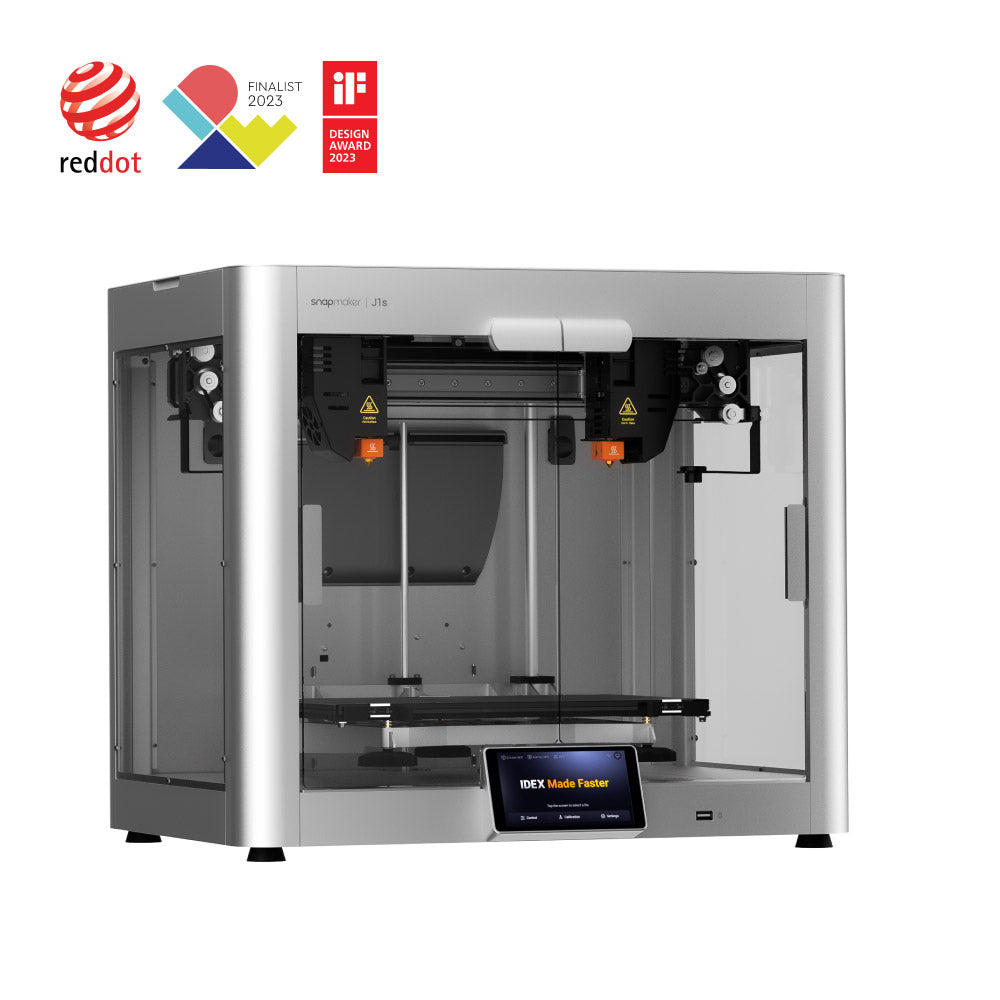

Snapmaker J1 Hochgeschwindigkeits-IDEX-3D-Drucker (inkl. MwSt.)

Der Snapmaker J1 3D-Drucker verfügt über einen unabhängigen Dual-Extruder (IDEX), ultraschnelle Druckgeschwindigkeit und Glättungsoptimierung. Mit gegossenen und bearbeiteten Bauteilen, linearen Schienen, intuitiver Software und benutzerzentrierten Designs zeichnet sich der J1 auch durch seine Feinheit und Robustheit aus.

Das Produkt enthält alles, was Sie brauchen, um Ihren Schöpfer-Trip zu beginnen.

Allgemeine Merkmale:

• Druckgeschwindigkeit von bis zu 350 mm/s und Beschleunigung von bis zu 10.000 mm/s²

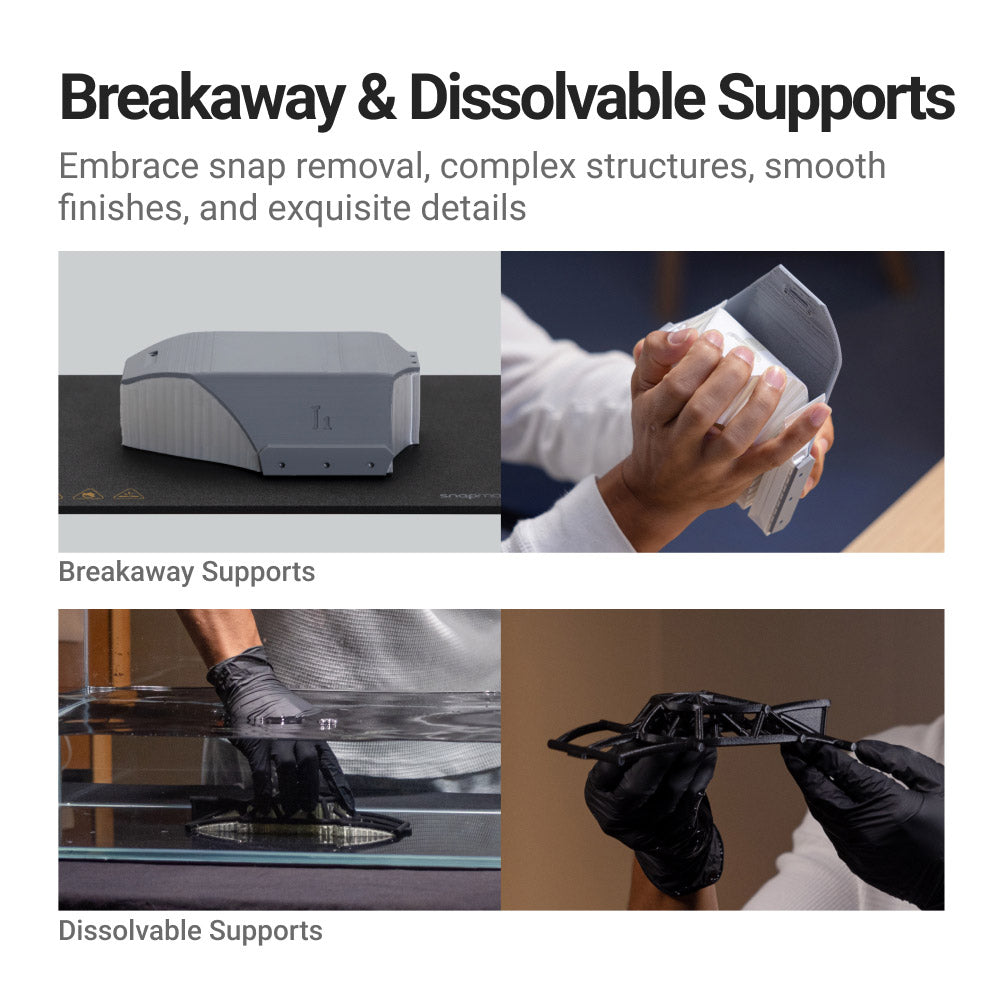

• Abbrechbare Supports und auflösbare Supports für müheloses Entfernen

• Kopier-Modus und Spiegel-Modus für doppelte Produktivität

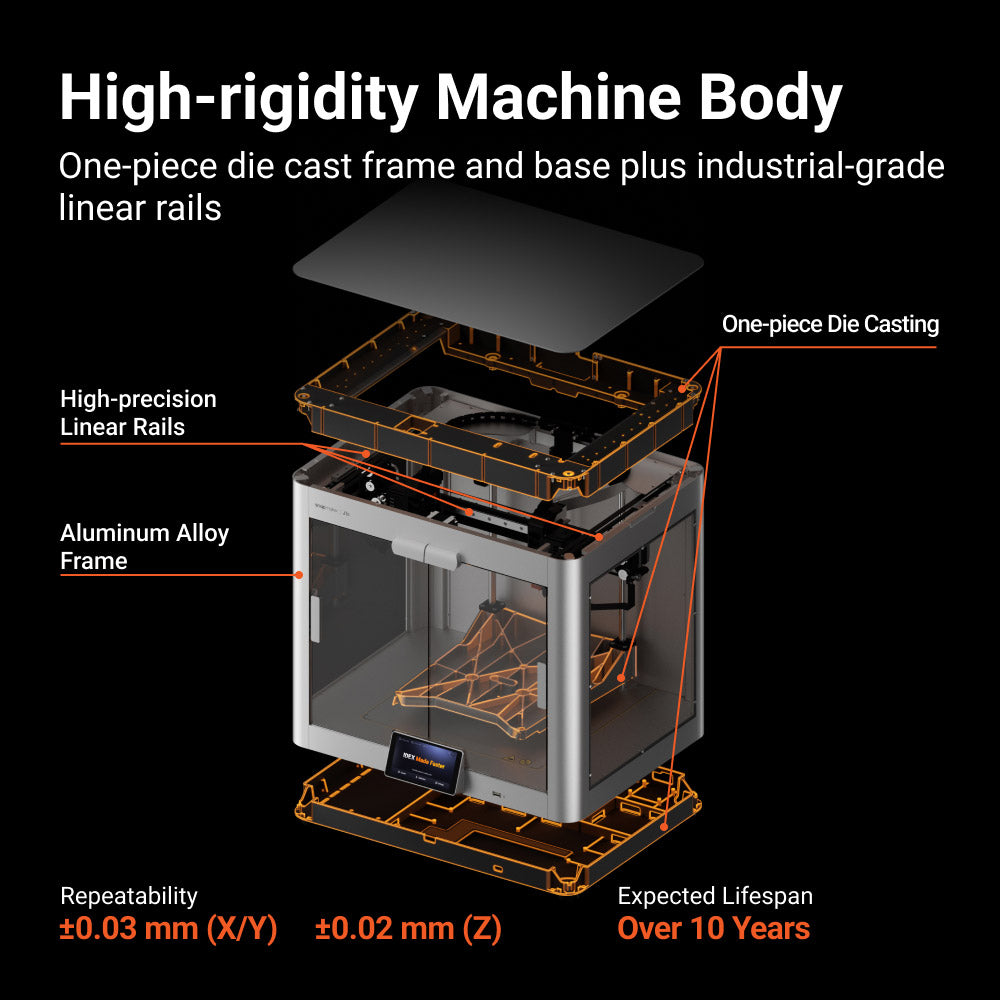

• Höchste Steifigkeit durch einteiligen Druckguss, hochpräzise Linearschienen und Rahmen aus Aluminiumlegierung

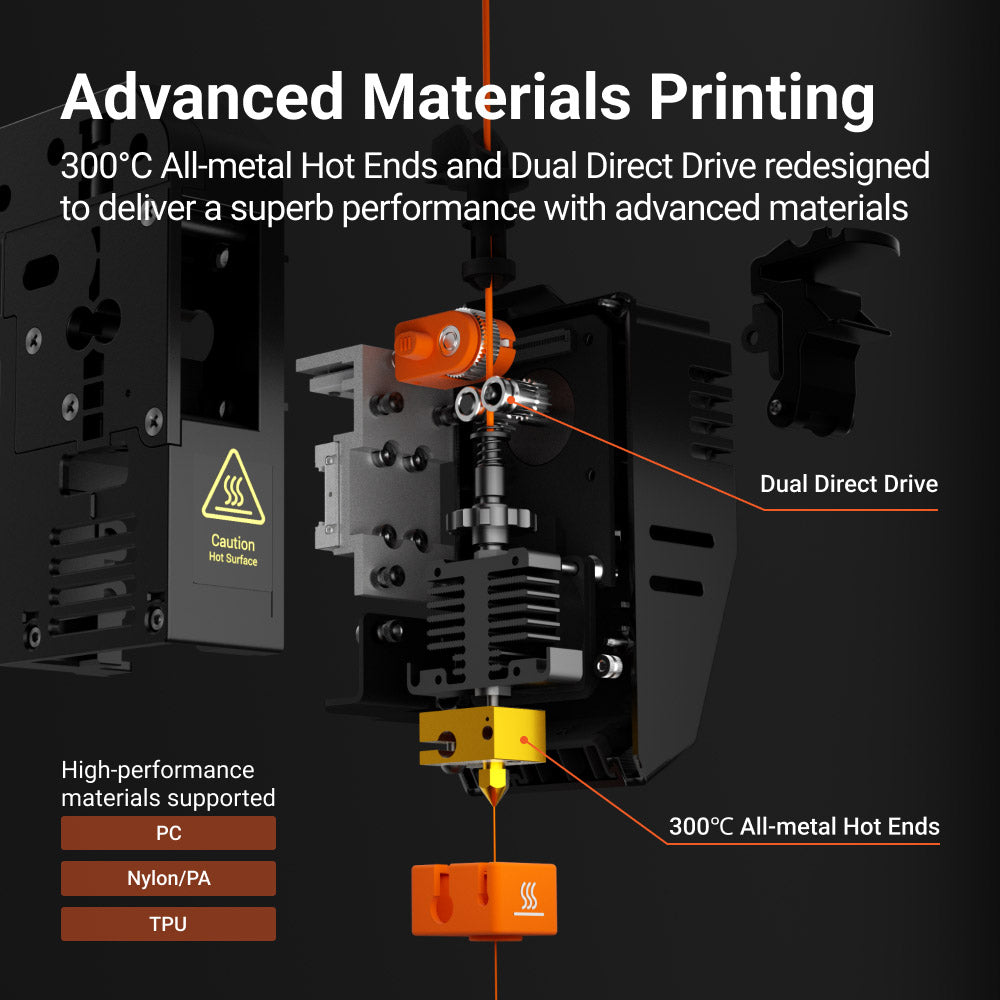

• Drucken mit fortschrittlichen Materialien, einschließlich Nylon, verstärktem Nylon, PC, TPU und PA-CF

• Intuitiver 5-Zoll-Touchscreen

Zwei Jahre Garantie inbegriffen. Inkl. MwSt.

4+ rolls at €19.99/roll, 8+ rolls at just €18.99/roll

SnapSpeed PLA Filament (1kg)

€22,90 €26,99

Matte PLA Filament (1kg)

€22,90 €23,99

PLA-Filament (1 kg)

€22,90 €28,99

PETG-Filament (1 kg)

€22,90 €28,99

ABS-Filament (1kg)

€22,90 €28,99

Verfügbarkeit für Abholungen konnte nicht geladen werden

Payment methods

Snapmaker J1s High Speed IDEX 3D Printer

IDEX made faster.

Print in Parallel

10,000mm/s2 Max. Acceleration

350mm/s Max. Speed

Intelligent IDEX Calibration

Less

Filament Waste

Dual-material Printing

Infinite possibilities with IDEX.

Copy mode & Mirror mode.

IDEX is the only extrusion system with two separate extruders moving independently on the X-axis, enabling you to run two prints simultaneously. Halve your wait time, double your productivity.

IDEXcel in dual-material printing.

In one print, you make the most of two sets of properties. Combine the strength of nylon with the flexibility of TPU for functional parts that can stand daily wear and tear impressively.

3D printing support structures.

J1s supports dissolvable and breakaway materials printing. Breakaway filament is much easier to remove without the need for further post-processing. Dissolvable support is right for complex geometry, hollow structures, and exquisite details.

Less waste & faster filament changing.

Compared with a multi-material unit, IDEX dual-material printing requires less time in filament changing and creates less waste.

High speed IDEX 3D printing.

Vibration compensation.

J1s brings you a top-of-class printing speed of 350 mm/s while ensuring a high resolution of prints. It is made possible by the optimization of the vibration compensation technology. With the maximum acceleration of 10,000 mm/s², you can realize small models packed with details with efficiency.

Seamless extruders switching.

The non-working extruder preheats while on standby, and starts printing right after the working extruder leaves, significantly reducing your waiting time.

Cornering optimization.

By analyzing the extruders' moving directions ahead of time, J1s is able to prevent problems like corner bulge, delivering better print quality at corners.

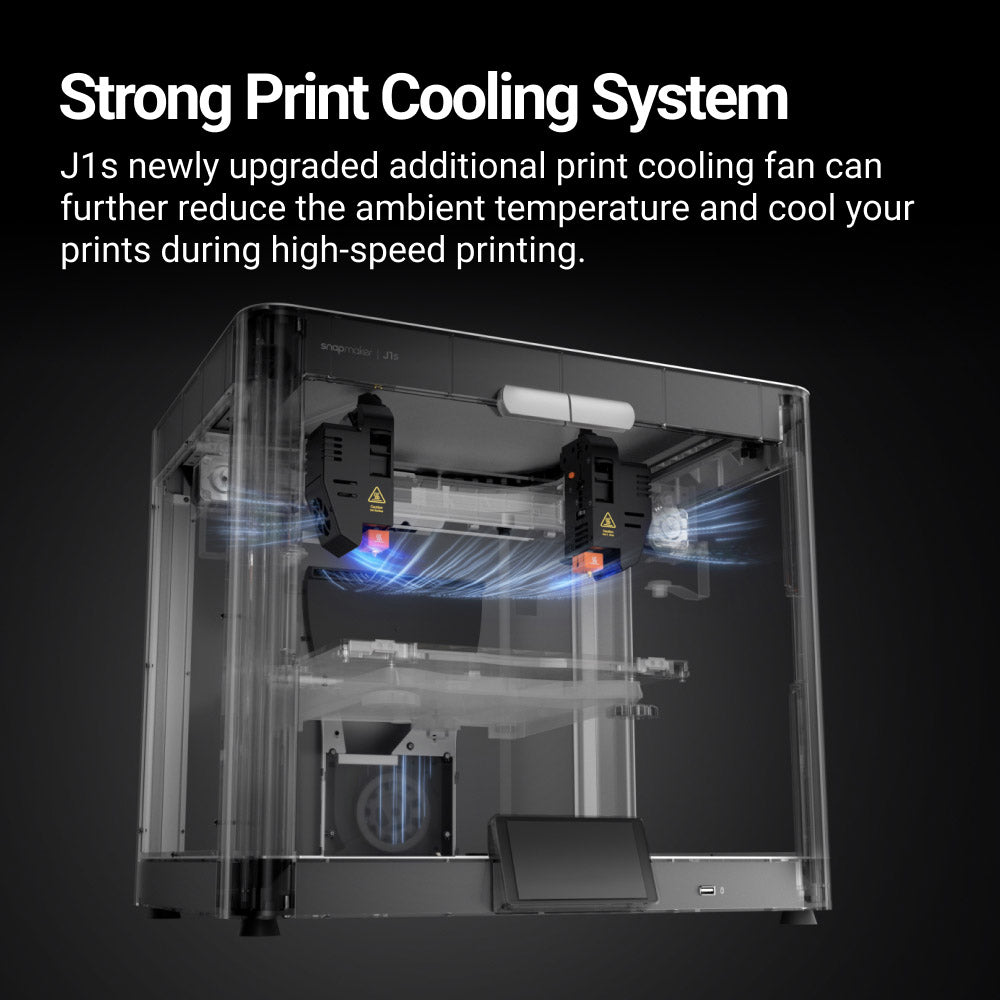

Strong print cooling system.

J1s has a strong print cooling system, comprising print cooling fans not only under the nozzles but also at the back panel. [1]

Innovative IDEX calibration.

Hands-free XY offset calibration.

When the two hot ends touch the square opening on the heated bed, it sends out electronic signals to suggest their exact locations, and J1s calculates the offsets between them. J1s then auto-compensates the offsets during printing to ensure perfect XY alignment that avoids layer shifting and improves the success rate of dual-material prints.

Tool-free bed leveling.

Using a PEI glass plate of high flatness, J1s can downsize from a 3 × 3 (9 points) or 4 × 4 (16 points) leveling to a 3-point one with no compromise on levelness and downtime dropped by 70–80%[2]. Turn the leveling wheel as guided on the touchscreen, and the bed is leveled for tip-top first-layer adhesion.

Easily-managed Z offset calibration.

Using electrical conduction, J1s can calculate the distances between the hot ends and the heated bed. Thus, we were able to cut the step of moving the calibration card back and forth while adjusting the Z offset.

User-friendly IDEX 3D slicer & Touchscreen.

Tailored IDEX 3D slicer in Luban.

Convenient dual-extruder configuration in Luban. Cura plugin is also provided for your convenience.

5-inch intuitive Touchscreen.

4 Printing Modes available. Dual-extruder configuration. Live display of working status.

Speed ensured by elaborate hardware design.

One-piece die casting.

The body of J1s comprises an upper frame and a base made by one-piece die casting, and four aluminum alloy bars. Making the body with just a few highly integrated parts—an approach long adopted by the automotive industry—facilitates precision assembly.

High-precision Linear Rails.

Repeatability[3]

±0.03 mm (X/Y)

±0.02 mm (Z)

Expected Lifespan[4]

Over 10 Years

Aluminum alloy frame.

J1s inherits Snapmaker's iconic all-metal design which users highly value for its rigidity and durability.

Essential accessories.

Easy-swap Hot Ends.

We offer multi-diameter hot ends from 0.2 mm for detail accuracy to 0.8 mm for faster printing, and hardened hot ends for engineering materials.

Custom PEI Glass Plate.

The build plate is made of glass with sheer flatness, making your first layer smooth and adhesive. Glossy glass on one side and PEI coating on the other side, aiding in adhesion for various filaments.

Built-in Nozzle Wipers.

Scrape excessive materials off nozzles and halt the oozing from the just-active extruder to free multi-material prints from blobs and stringing.

Pre-assembled & tuned.

Tuned and tested to its best condition.

Specifications

Printing Properties

Technology

Fused Filament Fabrication (FFF)

Extruder System

Independent Dual Extruders (IDEX)

Printing Modes

1. Default Mode

2. Backup Mode

3. Copy Mode

4. Mirror Mode

Build Volume

(W × D × H)

Default Mode & Backup Mode: 300 mm × 200 mm × 200 mm

Copy Mode: 160 mm × 200 mm × 200 mm

Mirror Mode: 150 mm × 200 mm × 200 mm

Layer Height

(with 0.4 mm nozzle)

0.05 mm–0.3 mm

Build Plate

PEI glass plate

Max. Heated Bed Temperature

100°C

Nozzle Diameter

0.4 mm (included)

0.2 mm, 0.6 mm, 0.8 mm, Hardened (optional)

Max. Nozzle Temperature

300°C

Filament Diameter

1.75 mm

Supported Materials[5]

PLA, ABS, HIPS, PC, TPU (Hardness ≥ 90 Shore A), TPE, PETG, ASA, PP, PVA, PA, PA-GF, PA-CF

Data Transmission Methods

Wi-Fi, USB cable, USB flash drive

Average Operating Noise

< 50 dBA

Machine Properties

Dimensions (W × D × H)

539 mm × 401 mm × 464 mm

Net Weight

25 kg (J1) ; 27.8 kg (J1s)

Touchscreen

Size: 5 in.

OS: Android

Resolution: 1280 × 720 pixels

Memory

1 GB RAM, 8 GB eMMC

Repeatability of Linear Rails[6]

± 0.03 mm (X/Y)

± 0.02 mm (Z)

Expected Lifespan of Linear Rails[7]

Over 10 Years

Operating Conditions

Operating Environment

Temperature: 10ºC–35ºC

Relative Humidity: 10%–90% (non-condensing)

Storage Environment

Temperature: -20ºC–55ºC

Relative Humidity: 10%–90% (non-condensing)

Power

Input

Rated Voltage: AC 100 V–240 V, 50 Hz/60 Hz

Rated Current: 4.4 A Max.

Output

DC 24 V, 400 W Max.

Software

Supplied Software

Luban (third-party software supported)

Supported OS of Luban

Windows, macOS, Linux (only tested on Ubuntu)

Supported File Formats

STL, OBJ, 3MF

Output File Formats

Gcode

In the Box (Snapmaker J1s)

Snapmaker J1s 3D Printer × 1

Print Cooling Fan × 1

PEI Glass Plate × 1

Orange PLA Filament × 1

Breakaway Support Filament × 1

Power Cable × 1

USB-B Cable × 1

Filament Holder × 2

Diagonal Pliers × 1

Tweezers × 1

USB Flash Drive × 1

Wire Brush × 1

Wiping Cloth × 1

Palette Knife × 1

Calibration Card × 1

Quick Start Guide × 1

Safety Guidelines × 1

Cable Clip × 1

M3 × 10 Screw × 8

5.5 mm Wrench × 1

H3.0 Hex Key × 1

H2.5 Hex Key × 1

H2.0 Hex Key × 1

H1.5 Hex Key × 1

Hot End Sock × 2

[1]The extra Print Cooling Fan is not included in the purchase of J1.

[2] The data may vary depending on the testing conditions and product iteration, and is for reference only.

[3] The data may vary depending on the testing conditions and product iteration, and is for reference only.

[4] The data is estimated based on the usage of printing at 100 mm/s for 24 hours per day. It may vary depending on the testing conditions and product iteration, and is for reference only.

[5] Hardened steel nozzle should be used when printing with PA, PA-GF, and PA-CF.

[6] The data may vary depending on the testing conditions and product iteration, and is for reference only.

[7] The data is estimated based on the usage of printing at 100 mm/s for 24 hours per day. It may vary depending on the testing conditions and product iteration, and is for reference only.

Frequently Asked Questions

1. What is an FFF 3D printer?

Fused Filament Fabrication (FFF) is an additive manufacturing technique that constructs objects by layer-by-layer extrusion of melted thermoplastics like ABS and Nylon, transforming digital designs into physical forms.

2. What is the build volume (W × D × H) of Snapmaker J1s 3D printer?

The Snapmaker J1s 3D Printer offers different printing dimensions based on the selected mode:

Default Mode & Backup Mode: 300 mm × 200 mm × 200 mm;

Copy Mode:160 mm × 200 mm × 200 mm;

Mirror Mode: 150 mm × 200 mm × 200 mm.

3. Can Snapmaker J1s print hollow structures?

Yes, the Snapmaker J1s 3D printer can print hollow structures. Its support for dissolvable materials like PVA allows for creating complex geometries and hollow interiors. After printing, the supports inside hollow sections can be dissolved away, leaving clean, detailed internal surfaces.

4. How does Snapmaker J1s 3D printer eliminate corner bulge?

Snapmaker J1s 3D printer uses cornering optimization technology to improve the quality of 3D prints at the edges. By analyzing and adjusting the movement of the extruders before they reach the corners, it prevents excess filament from piling up, which helps keep the corners sharp and accurate.

5. How does the cooling system enhance the performance of the Snapmaker J1s 3D Printer?

Cooling is crucial for accuracy and detail as it quickly solidifies each filament layer. The Snapmaker J1s excels with a powerful cooling system that features additional fans not only under the nozzles but also at the back panel.

6. How does the Snapmaker J1s ensure consistent first-layer printing?

The Snapmaker J1s ensures consistent first-layer printing through its advanced leveling technology. This technology allows the printer to maintain a uniform layer thickness across different points on the bed, establishing a strong foundation for subsequent layers and improving overall print quality.

7. How to clean your J1s IDEX 3D printer nozzle in printing routines?

• Turn off the printer and wait for the nozzle to cool down, then disassemble the nozzle and clean its outer surface with a cotton swab dipped in anhydrous ethanol. Please take protective measures beforehand, such as putting on gloves.

• Start the printer and heat the nozzle, then clean it with tweezers after the filament on the outside of the nozzle is melted.

• If you do not want to turn on the printer, you can detach the nozzle and then heat it with a heat gun before performing the cleaning. But you need to be careful to prevent burns.

Snapmaker J1s High Speed IDEX 3D Printer

IDEX made faster.

Print in Parallel

10,000mm/s2

Max. Acceleration

350mm/s Max. Speed

Intelligent IDEX Calibration

Less

Filament Waste

Dual-material Printing

Infinite possibilities with IDEX.

Copy mode & Mirror mode.

IDEX is the only extrusion system with two separate extruders moving independently on the X-axis, enabling you to run two prints simultaneously. Halve your wait time, double your productivity.

IDEXcel in dual-material printing.

In one print, you make the most of two sets of properties. Combine the strength of nylon with the flexibility of TPU for functional parts that can stand daily wear and tear impressively.

3D printing support structures.

J1s supports dissolvable and breakaway materials printing. Breakaway filament is much easier to remove without the need for further post-processing. Dissolvable support is right for complex geometry, hollow structures, and exquisite details.

Less waste & faster filament changing.

Compared with a multi-material unit, IDEX dual-material printing requires less time in filament changing and creates less waste.

High speed IDEX 3D printing.

Vibration compensation.

J1s brings you a top-of-class printing speed of 350 mm/s while ensuring a high resolution of prints. It is made possible by the optimization of the vibration compensation technology. With the maximum acceleration of 10,000 mm/s², you can realize small models packed with details with efficiency.

Seamless extruders switching.

The non-working extruder preheats while on standby, and starts printing right after the working extruder leaves, significantly reducing your waiting time.

Cornering optimization.

By analyzing the extruders' moving directions ahead of time, J1s is able to prevent problems like corner bulge, delivering better print quality at corners.

Strong print cooling system.

J1s has a strong print cooling system, comprising print cooling fans not only under the nozzles but also at the back panel.[1]

Innovative IDEX calibration.

Hands-free XY offset calibration.

When the two hot ends touch the square opening on the heated bed, it sends out electronic signals to suggest their exact locations, and J1s calculates the offsets between them. J1s then auto-compensates the offsets during printing to ensure perfect XY alignment that avoids layer shifting and improves the success rate of dual-material prints.

Tool-free bed leveling.

Using a PEI glass plate of high flatness, J1s can downsize from a 3 × 3 (9 points) or 4 × 4 (16 points) leveling to a 3-point one with no compromise on levelness and downtime dropped by 70–80%[2]. Turn the leveling wheel as guided on the touchscreen, and the bed is leveled for tip-top first-layer adhesion.

Easily-managed Z offset calibration.

Using electrical conduction, J1s can calculate the distances between the hot ends and the heated bed. Thus, we were able to cut the step of moving the calibration card back and forth while adjusting the Z offset.

User-friendly IDEX 3D slicer & Touchscreen.

Tailored IDEX 3D slicer in Luban.

Convenient dual-extruder configuration in Luban. Cura plugin is also provided for your convenience.

5-inch intuitive Touchscreen.

4 Printing Modes available. Dual-extruder configuration. Live display of working status.

Speed ensured by elaborate hardware design.

One-piece die casting.

The body of J1s comprises an upper frame and a base made by one-piece die casting, and four aluminum alloy bars. Making the body with just a few highly integrated parts—an approach long adopted by the automotive industry—facilitates precision assembly.

High-precision Linear Rails.

Repeatability[3]

±0.03 mm (X/Y)

±0.02 mm (Z)

Expected Lifespan[4]

Over 10 Years

Aluminum alloy frame.

J1s inherits Snapmaker's iconic all-metal design which users highly value for its rigidity and durability.

Essential accessories.

Easy-swap Hot Ends.

We offer multi-diameter hot ends from 0.2 mm for detail accuracy to 0.8 mm for faster printing, and hardened hot ends for engineering materials.

Custom PEI Glass Plate.

The build plate is made of glass with sheer flatness, making your first layer smooth and adhesive. Glossy glass on one side and PEI coating on the other side, aiding in adhesion for various filaments.

Built-in Nozzle Wipers.

Scrape excessive materials off nozzles and halt the oozing from the just-active extruder to free multi-material prints from blobs and stringing.

Pre-assembled & tuned.

Tuned and tested to its best condition.

Specifications

Printing Properties

Technology

Fused Filament Fabrication (FFF)

Extruder System

Independent Dual Extruders (IDEX)

Printing Modes

1. Default Mode

2. Backup Mode

3. Copy Mode

4. Mirror Mode

Build Volume

(W × D × H)

Default Mode & Backup Mode: 300 mm × 200 mm × 200 mm

Copy Mode: 160 mm × 200 mm × 200 mm

Mirror Mode: 150 mm × 200 mm × 200 mm

Layer Height

(with 0.4 mm nozzle)

0.05 mm–0.3 mm

Build Plate

PEI glass plate

Max. Heated Bed Temperature

100°C

Nozzle Diameter

0.4 mm (included)

0.2 mm, 0.6 mm, 0.8 mm, Hardened (sold separately)

Max. Nozzle Temperature

300°C

Filament Diameter

1.75 mm

Supported Materials[5]

PLA, ABS, HIPS, PC, TPU (Hardness ≥ 90 Shore A), TPE, PETG, ASA, PP, PVA, PA, PA-GF, PA-CF

Data Transmission Methods

Wi-Fi, USB cable, USB flash drive

Average Operating Noise

< 50 dBA

Machine Properties

Dimensions (W × D × H)

539 mm × 401 mm × 464 mm

Net Weight

25 kg (J1); 27.8 kg (J1s)

Touchscreen

Size: 5 in.

OS: Android

Resolution: 1280 × 720 pixels

Memory

1 GB RAM, 8 GB eMMC

Repeatability of Linear Rails[6]

± 0.03 mm (X/Y)

± 0.02 mm (Z)

Expected Lifespan of Linear Rails[7]

Over 10 Years

Operating Conditions

Operating Environment

Temperature: 10ºC–35ºC

Relative Humidity: 10%–90% (non-condensing)

Storage Environment

Temperature: -20ºC–55ºC

Relative Humidity: 10%–90% (non-condensing)

Power

Input

Rated Voltage: AC 100 V–240 V, 50 Hz/60 Hz

Rated Current: 4.4 A Max.

Output

DC 24 V, 400 W Max.

Software

Supplied Software

Luban (third-party software supported)

Supported OS of Luban

Windows, macOS, Linux (only tested on Ubuntu)

Supported File Formats

STL, OBJ, 3MF

Output File Formats

Gcode

In the Box (Snapmaker J1s)

Snapmaker J1s 3D Printer × 1

Print Cooling Fan × 1

PEI Glass Plate × 1

Orange PLA Filament × 1

Breakaway Support Filament × 1

Power Cable × 1

USB-B Cable × 1

Filament Holder × 2

Diagonal Pliers × 1

Tweezers × 1

USB Flash Drive × 1

Wire Brush × 1

Wiping Cloth × 1

Palette Knife × 1

Calibration Card × 1

Quick Start Guide × 1

Safety Guidelines × 1

Cable Clip × 1

M3 × 10 Screw × 8

5.5 mm Wrench × 1

H3.0 Hex Key × 1

H2.5 Hex Key × 1

H2.0 Hex Key × 1

H1.5 Hex Key × 1

Hot End Sock × 2

[1] The extra Print Cooling Fan is not included in the purchase of J1.

[2] The data may vary depending on the testing conditions and product iteration, and is for reference only.

[3] The data may vary depending on the testing conditions and product iteration, and is for reference only.

[4] The data is estimated based on the usage of printing at 100 mm/s for 24 hours per day. It may vary depending on the testing conditions and product iteration, and is for reference only.

[5] Hardened steel nozzle should be used when printing with PA, PA-GF, and PA-CF.

[6] The data may vary depending on the testing conditions and product iteration, and is for reference only.

[7] The data is estimated based on the usage of printing at 100 mm/s for 24 hours per day. It may vary depending on the testing conditions and product iteration, and is for reference only.

Frequently Asked Questions

1. What is an FFF 3D printer?

Fused Filament Fabrication (FFF) is an additive manufacturing technique that constructs objects by layer-by-layer extrusion of melted thermoplastics like ABS and Nylon, transforming digital designs into physical forms.

2. What is the build volume (W × D × H) of Snapmaker J1s 3D printer?

The Snapmaker J1s 3D Printer offers different printing dimensions based on the selected mode:

Default Mode & Backup Mode: 300 mm × 200 mm × 200 mm;

Copy Mode:160 mm × 200 mm × 200 mm;

Mirror Mode: 150 mm × 200 mm × 200 mm.

3. Can Snapmaker J1s print hollow structures?

Yes, the Snapmaker J1s 3D printer can print hollow structures. Its support for dissolvable materials like PVA allows for creating complex geometries and hollow interiors. After printing, the supports inside hollow sections can be dissolved away, leaving clean, detailed internal surfaces.

4. How does Snapmaker J1s 3D printer eliminate corner bulge?

Snapmaker J1s 3D printer uses cornering optimization technology to improve the quality of 3D prints at the edges. By analyzing and adjusting the movement of the extruders before they reach the corners, it prevents excess filament from piling up, which helps keep the corners sharp and accurate.

5. How does the cooling system enhance the performance of the Snapmaker J1s 3D Printer?

Cooling is crucial for accuracy and detail as it quickly solidifies each filament layer. The Snapmaker J1s excels with a powerful cooling system that features additional fans not only under the nozzles but also at the back panel.

6. How does the Snapmaker J1s ensure consistent first-layer printing?

The Snapmaker J1s ensures consistent first-layer printing through its advanced leveling technology. This technology allows the printer to maintain a uniform layer thickness across different points on the bed, establishing a strong foundation for subsequent layers and improving overall print quality.

7. How to clean your J1s IDEX 3D printer nozzle in printing routines?

• Turn off the printer and wait for the nozzle to cool down, then disassemble the nozzle and clean its outer surface with a cotton swab dipped in anhydrous ethanol. Please take protective measures beforehand, such as putting on gloves.

• Start the printer and heat the nozzle, then clean it with tweezers after the filament on the outside of the nozzle is melted.

• If you do not want to turn on the printer, you can detach the nozzle and then heat it with a heat gun before performing the cleaning. But you need to be careful to prevent burns.