FAQs

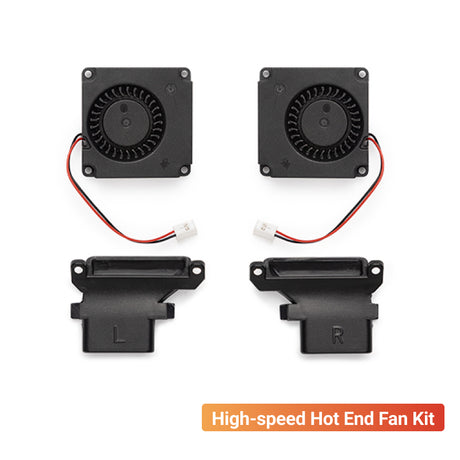

Hochgeschwindigkeits-Heißluftgebläse-Kit für Snapmaker J1/J1s

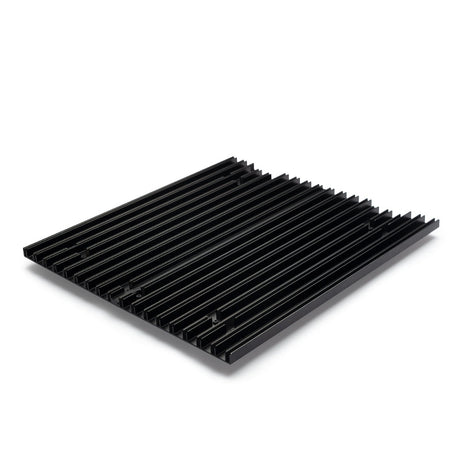

Von €13,59 EUR€16,99Grundpreis /Nicht verfügbarAuf LagerLasergravur- und Schneideplattform für Snapmaker Artisan

€63,20 EUR€79,00Grundpreis /Nicht verfügbarSehr geringer Bestand

1. What can I find in the New Releases page?

The New Releases collection offers Snapmaker's latest products, including advanced 3D printers, laser modules, CNC tools, and accessories.

2. When will my order ship?

In-stock orders typically ship within 1-5 business days. For pre-orders, the estimated shipping date will be displayed on the product page. Once your order ships, you will receive a shipping confirmation email with a tracking number. You can also check your order status here.

3. What is the shipping cost?

Shipping costs will be calculated at checkout based on the weight and destination of the package. Free shipping will be provided for EU/CA/UK/US (excluding AK, HI, PR, AE, and AP) users when the order amount exceeds $/€99.

4. Does Snapmaker offer a 30-Day Price Guarantee for new products?

Yes, we offer a 30-day price guarantee on all products bought directly from the Snapmaker Official Online Store. For full details, please refer to our 30-day price guarantee policy.

5. How can I stay updated about Snapmaker new product launches?

To stay updated on Snapmaker's new products and promotions, we recommend bookmarking this page for easy access. You can also subscribe to our newsletter or follow us on social media for the latest updates.

FAQs

1. What can I find in the New Releases page?

The New Releases collection offers Snapmaker's latest products, including advanced 3D printers, laser modules, CNC tools, and accessories.

2. When will my order ship?

In-stock orders typically ship within 1-5 business days. For pre-orders, the estimated shipping date will be displayed on the product page. Once your order ships, you will receive a shipping confirmation email with a tracking number. You can also check your order status here.

3. What is the shipping cost?

Shipping costs will be calculated at checkout based on the weight and destination of the package. Free shipping will be provided for EU/CA/UK/US (excluding AK, HI, PR, AE, and AP) users when the order amount exceeds $/€99.

4. Does Snapmaker offer a 30-Day Price Guarantee for new products?

Yes, we offer a 30-day price guarantee on all products bought directly from the Snapmaker Official Online Store. For full details, please refer to our 30-day price guarantee policy.

5. How can I stay updated about Snapmaker new product launches?

To stay updated on Snapmaker's new products and promotions, we recommend bookmarking this page for easy access. You can also subscribe to our newsletter or follow us on social media for the latest updates.