FAQs

- Von €18,89 EUR

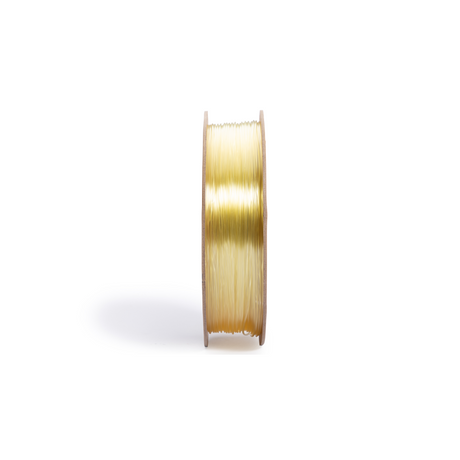

€26,99Grundpreis /Nicht verfügbar+3Auf Lager - Von €6,00 EUR

€11,99Grundpreis /Nicht verfügbarAuf Lager Grünes PLA-Filament, das im Dunkeln leuchtet (1kg)

€31,99 EURGrundpreis /Nicht verfügbarSchwarzes High Flow TPU95 Filament (1kg)

€50,99 EURGrundpreis /Nicht verfügbar

1. Welche Holzarten werden häufig für das Lasergravieren und -schneiden verwendet?

Häufig verwendete Holzarten sind:

• Linde: Weichholz mit feiner Maserung, gut zum Gravieren und Schneiden geeignet.

• Erle: Harzhaltig, bietet hohen Kontrast beim Gravieren.

• Kirsche: Hartholz, glatt zum Gravieren und Schneiden.

• Sperrholz: Stabil und ideal zum Laserschneiden, aber Vorsicht wegen Rauchentwicklung durch Klebstoff.

• MDF: Glatt und fest, aber wegen Harzgehalt nicht ideal zum Schneiden.

2. Kann ich MDF mit dem Laser schneiden?

Ja, es hat eine glatte Oberfläche und ist für präzises Schneiden und Gravieren mit dem Snapmaker Laser-Modul geeignet.

3. Gibt es Materialien, die ich mit dem Snapmaker Laser-Modul vermeiden sollte?

Vermeiden Sie Materialien, die stark reflektierend sind (außer 304 Edelstahl und eloxiertes Aluminium), da sie Laserlicht reflektieren und das Risiko von Feuer oder Schäden am Laser-Modul erhöhen können. Verwenden Sie außerdem keine brennbaren, explosiven oder giftigen Materialien, die ein Sicherheitsrisiko darstellen oder gefährliche Dämpfe erzeugen könnten.

4. Welche Materialien sind mit dem Snapmaker 2.0 50W CNC-Modul kompatibel?

Kompatible Materialien sind Holz, Acryl, PCB, Carbonfaserplatten, Jade usw.

5. Kann ich PLA-Material für den 3D-Drucker im Außenbereich verwenden?

Nein, PLA ist biologisch abbaubar und nicht ideal für den Außeneinsatz aufgrund von:

• UV-Abbau: Sonnenlicht kann PLA zersetzen und die Festigkeit beeinträchtigen.

• Feuchtigkeitsaufnahme: PLA nimmt Feuchtigkeit auf, was zu Brüchigkeit führt.

Für Anwendungen im Außenbereich sollten Sie 3D-Drucker-Materialien wie ABS oder PETG verwenden, die eine bessere UV-Beständigkeit und Haltbarkeit bieten.

6. Wie befestige ich das Material am Rotary Module?

So sichern Sie Ihr Material:

1. Drei-Backen-Futter lösen: Verwenden Sie zwei Spannschlüssel, um das Futter gegen den Uhrzeigersinn zu drehen.

2. Material einsetzen: Platzieren Sie ein Ende des Materials in die dreistufigen Backen.

3. Futter festziehen: Drehen Sie das Futter im Uhrzeigersinn, um das Material sicher zu halten.

Hinweis: Verwenden Sie immer zwei Spannschlüssel zum Einstellen der Backen, da sie sehr scharf sind.

FAQs

1. Welche Holzarten werden häufig für das Lasergravieren und -schneiden verwendet?

Häufig verwendete Holzarten sind:

• Linde: Weichholz mit feiner Maserung, gut zum Gravieren und Schneiden geeignet.

• Erle: Harzhaltig, bietet hohen Kontrast beim Gravieren.

• Kirsche: Hartholz, glatt zum Gravieren und Schneiden.

• Sperrholz: Stabil und ideal zum Laserschneiden, aber Vorsicht wegen Rauchentwicklung durch Klebstoff.

• MDF: Glatt und fest, aber wegen Harzgehalt nicht ideal zum Schneiden.

2. Kann ich MDF mit dem Laser schneiden?

Ja, es hat eine glatte Oberfläche und ist für präzises Schneiden und Gravieren mit dem Snapmaker Laser-Modul geeignet.

3. Gibt es Materialien, die ich mit dem Snapmaker Laser-Modul vermeiden sollte?

Vermeiden Sie Materialien, die stark reflektierend sind (außer 304 Edelstahl und eloxiertes Aluminium), da sie Laserlicht reflektieren und das Risiko von Feuer oder Schäden am Laser-Modul erhöhen können. Verwenden Sie außerdem keine brennbaren, explosiven oder giftigen Materialien, die ein Sicherheitsrisiko darstellen oder gefährliche Dämpfe erzeugen könnten.

4. Welche Materialien sind mit dem Snapmaker 2.0 50W CNC-Modul kompatibel?

Kompatible Materialien sind Holz, Acryl, PCB, Carbonfaserplatten, Jade usw.

5. Kann ich PLA-Material für den 3D-Drucker im Außenbereich verwenden?

Nein, PLA ist biologisch abbaubar und nicht ideal für den Außeneinsatz aufgrund von:

• UV-Abbau: Sonnenlicht kann PLA zersetzen und die Festigkeit beeinträchtigen.

• Feuchtigkeitsaufnahme: PLA nimmt Feuchtigkeit auf, was zu Brüchigkeit führt.

Für Anwendungen im Außenbereich sollten Sie 3D-Drucker-Materialien wie ABS oder PETG verwenden, die eine bessere UV-Beständigkeit und Haltbarkeit bieten.

6. Wie befestige ich das Material am Rotary Module?

So sichern Sie Ihr Material:

1. Drei-Backen-Futter lösen: Verwenden Sie zwei Spannschlüssel, um das Futter gegen den Uhrzeigersinn zu drehen.

2. Material einsetzen: Platzieren Sie ein Ende des Materials in die dreistufigen Backen.

3. Futter festziehen: Drehen Sie das Futter im Uhrzeigersinn, um das Material sicher zu halten.

Hinweis: Verwenden Sie immer zwei Spannschlüssel zum Einstellen der Backen, da sie sehr scharf sind.