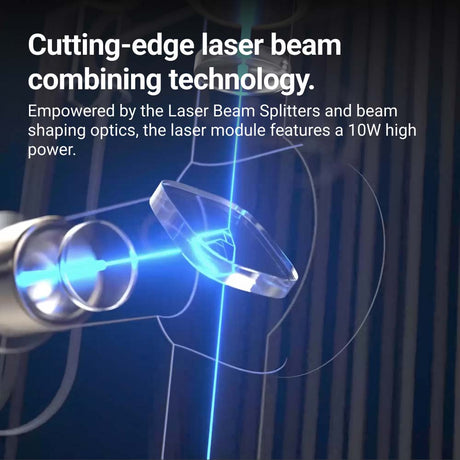

Snapmaker 10W High Power Laser Module (VAT Incl.)

From €329,00 EUR€519,00Unit price /UnavailableIn stockSnapmaker Rotary Module (Harmonic Drive Version) (VAT Incl.)

From €459,00 EUR€639,00Unit price /UnavailableIn stockSnapmaker 2.0 Dual Extrusion 3D Printing Module

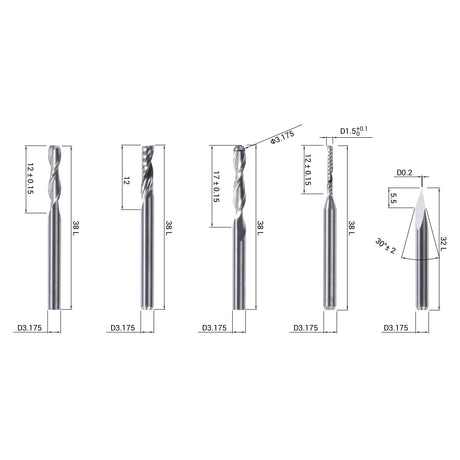

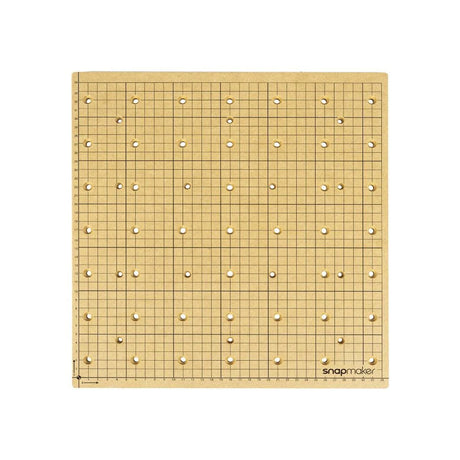

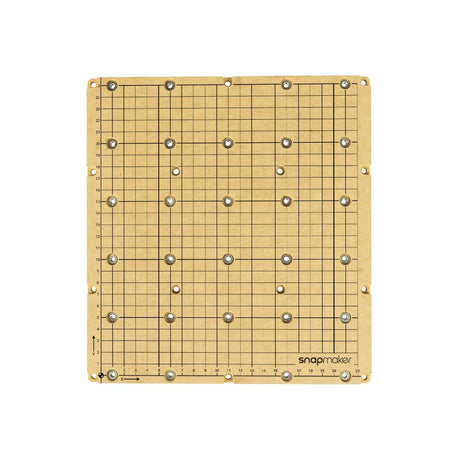

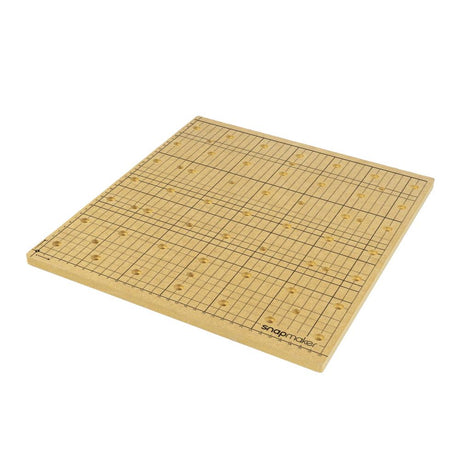

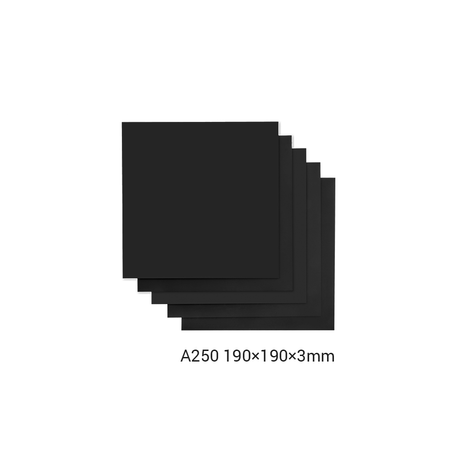

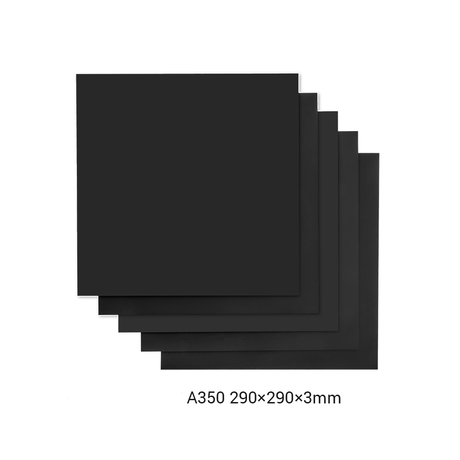

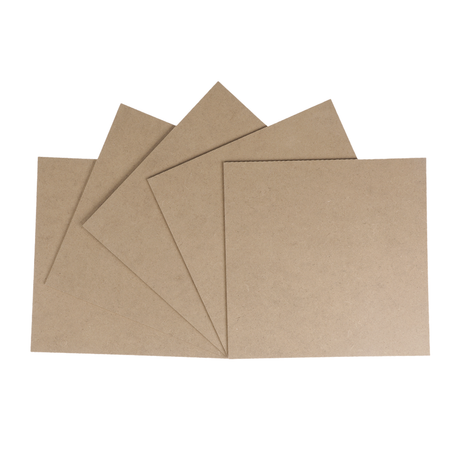

€499,00 EUR€699,00Unit price /UnavailableIn stockCNC Platform (MDF Wasteboard) for Snapmaker 2.0

From €11,50 EUR€22,99Unit price /UnavailableIn stock

How can you experiment with different materials and cutting techniques to create unique textures, shapes, or patterns in your CNC-cut products?

How do the properties and characteristics of materials impact the overall performance and durability of CNC-cut products, and what are some ways to improve quality and consistency?

What are the different types of materials that can be cut using lasers, such as metals, plastics, wood, or fabrics, and how do they differ in terms of optical properties, thermal conductivity, and reflectivity?

How do you choose the right material for your laser cutting project, such as considering factors like thickness, texture, color, or cost?

How to maintain the safety of the printer, such as fire prevention, explosion protection, electromagnetic radiation?

1. Fire prevention:

a. Keep the 3D printer in a well-ventilated area, away from flammable materials and liquids.

b. Regularly clean the print bed and the printer's components to remove dust, debris, and accumulated filament.

c. Install a smoke detector near the 3D printer to detect any potential fire hazards early.

d. Always monitor the printer during operation, and avoid leaving it unattended for long periods.

2. Explosion protection:

a. Ensure that the printer is in a well-ventilated area to avoid the buildup of potentially explosive fumes, especially when working with volatile materials or solvents.

b. Store and handle any chemicals or solvents used in the printing process according to the manufacturer's safety guidelines.

c. Use only approved and compatible materials for your specific 3D printer to avoid potential chemical reactions or explosions.

3. Electromagnetic radiation:

a. Use a grounded power supply and ensure proper electrical grounding for the 3D printer to reduce the risk of electrical interference or radiation.

b. Keep the 3D printer away from sensitive electronic devices, as some printers may emit electromagnetic radiation that could interfere with their operation.

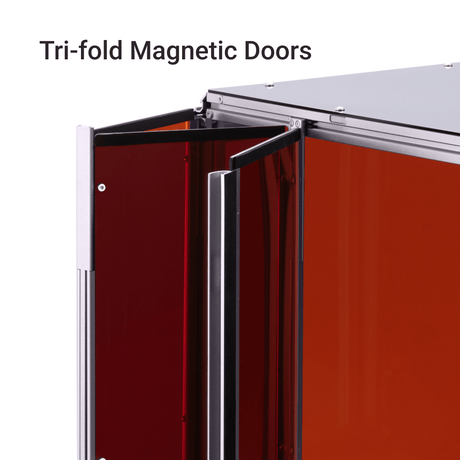

c. If your 3D printer has an enclosure, consider using materials with shielding properties to minimize electromagnetic radiation.

4. General safety tips:

a. Read and follow the manufacturer's guidelines and safety precautions for your specific 3D printer model.

b. Keep the 3D printer away from children and pets.

c. Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when handling the printer, hot components, or chemicals.

d. Regularly inspect the printer's components for wear, damage, or loose connections, and repair or replace them as needed.

e. Keep the printer's firmware up-to-date to ensure the latest safety features and improvements are in place.