Find the right Snapmaker 3D printer for you

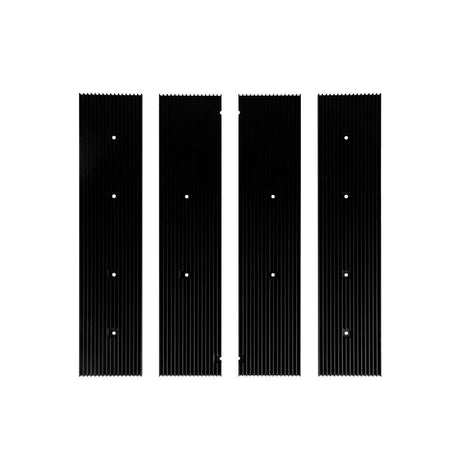

Laser Engraving and Cutting Platform for Snapmaker 2.0

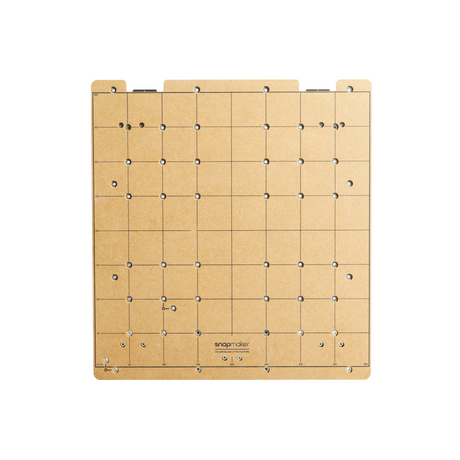

From €19,50 EUR€39,00Unit price /UnavailableIn stockSnapmaker Artisan Quick Swap Toolhead Plate (Adjustable Version)

€16,99 EURUnit price /UnavailableAir passage and proximity sensor kit for Snapmaker 2.0 3D Printing Module

€6,00 EURUnit price /UnavailableIn stock

Find the right Snapmaker 3D printer for you

J1

A350T/A250T

Artisan

High Speed IDEX

3-in-1

3-in-1

MSRP:

€1699

MSRP:

€1949~€2349

MSRP:

€3299

Basic Information

Standard 3D Printing Function

Independent Dual Extrusion (IDEX)

Single Extrusion

Dual Extrusion

Standard Laser Function

-

1600mW

10W

Standard CNC Function

-

50W

200W

Standard Enclosure

Equipped

Equipped

Equipped

Work Area

(W × D × H)

Default Mode & Backup Mode:

300mm x 200mm x 200mm

Copy Mode:

160mm x 200mm x 200mm

Mirror Mode:

150mm x 200mm x 200mm

Single Extrusion Module:

230 × 250 × 235 mm (A250T)

320 × 350 × 330 mm (A350T)

Dual Extrusion:

350 × 400 × 400 mm

Enclosure Dimensions

(W × D × H)

539 × 401 × 464 mm

624 × 530 × 507 mm (A250T)

820 × 626 × 603 mm (A350T)

665 × 943 × 705 mm

Maximum Printing Speed

350 mm/s

100 mm/s

300 mm/s

Maximum Acceleration

10,000 mm/s2

1,000 mm/s2

2,000 mm/s2

Maximum Nozzle Temperature

300°C

275°C

300°C

Rated Power

400W

320W

350W + 400W

Software

Luban

Luban

Luban

Expandability

Enclosure

-

Equipped

Equipped

Quick-swap Design

-

×(Available Soon)

√

Motion System

Motor Driver Chip of Linear Module

TMC2209

TMC2209

TMC2209

X-axis Lead

40 mm

20 mm

40 mm

Y-axis Lead

40 mm

20 mm

40 mm

Z-axis Lead

2 mm

8 mm

8 mm

Transmission System

Industrial Linear Rail

Lead Screw

Embedded Steel Guiderail

3D Printing

Build Plate

PEI-coated Glass

Steel Plate with PC

Stickers on Both Sides

PEI-coated Glass

Supported Nozzle

Diameter

Standard:

0.4 mm Brass Nozzle ×2

Optional:

0.2 mm Brass Nozzle,

0.6 mm Brass Nozzle,

0.8 mm Brass Nozzle,

0.4 mm Hardened Nozzle

Standard:

0.4 mm Brass Nozzle

Standard:

0.4 mm Brass Nozzle ×2

Optional:

0.2 mm Brass Nozzle,

0.6 mm Brass Nozzle,

0.8 mm Brass Nozzle,

0.4 mm Hardened Nozzle

High-temperature Zone

×

×

260 mm × 260 mm

Zone Heating

×

×

√

Heating Speed of

Heated Bed

Heating up to

60°C in 4 min

Heating up to

60°C in 4 to 5 min

High-temperature Zone:

Heating up to 60°C in 2 to 3 min

The Whole Heated Zone:

Heating up to 60°C in 4 to 5 min

Maximum Temperature

of Heated Bed

100°C

100°C (A250T)

80°C (A350T)

High-temperature

Zone: 110°C

Outer Zone: 80°C

Supported Materials

PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, PA, PA-GF, PA-CF

PLA, ABS, PETG, TPU

PLA, ABS, PETG, TPU, PVA,

Breakaway PLA, HIPS,

PA-CF, PA-GF, ASA

Laser Engraving and Cutting

1600mW Laser Module

-

Equipped

Optional

10W Laser Module

-

Optional

Standard

Maximum

Engraving Speed

-

15 mm/s

100 mm/s

Maximum Cutting Depth

-

1.5 mm Paulownia

8 mm Paulownia

Standard Camera

-

No Wide Angle

Wide Angle

Supported

Engraving Materials

-

Basswood, Paulownia, Pinewood, Plywood, Bamboo, Leather, Fabric, Paper, Dark Acrylic (Blue excluded)

Basswood, Paulownia, Pinewood, Plywood, Beech, Walnut, Bamboo, MDF, Painted Metal, Copper Clad Laminate, Tinplate, Stainless Steel, Anodized Aluminum, Dark Glass, Slate, Ceramics, Jade, Marble, Shale, Leather, Fabric, Canvas, Corrugated Paper, Cardboard, Plastic, Dark Acrylic (Blue excluded)

Supported Cutting

Materials

-

Basswood, Paulownia, Pinewood, Plywood, Paper, Dark Acrylic (Blue excluded)

Basswood, Paulownia, Pinewood, Plywood, Beech, Walnut, Bamboo, MDF, Leather, Fabric, Canvas, Corrugated Paper, Cardboard, Plastic, Dark Acrylic (Blue excluded)

Work Area (W × D)

-

230 × 250 mm (A250T)

320 × 350 mm (A350T)

400 × 400 mm

CNC Carving

50W CNC Module

-

Equipped

Optional

200W CNC Module

-

Incompatible

Equipped

Maximum Spindle Speed

-

12,000 RPM

18,000 RPM

Maximum Work Speed[1]

-

Beech: 16 mm/s

Acrylic: 10 mm/s

Beech: 50 mm/s

Acrylic: 33 mm/s

Maximum Stepdown

-

Beech: 1 mm

Acrylic: 0.5 mm

Beech: 2 mm

Acrylic: 1 mm

Supported Materials

-

Hardwood (Beech, Walnut), Softwood, Acrylic, PCB, Carbon Fiber, Jade

Hardwood (Beech, Walnut), Softwood, HDF, MDF, Plywood, Jade, Carbon Fiber, Acrylic, Epoxy Tooling Board, PCB

Work Area (W × D × H)

-

230 × 250 × 180 mm (A250T)

320 × 350 × 275 mm (A350T)

400 mm × 400 mm × 400 mm

[1] The data is obtained by cutting beech with 3.175 mm Double Flute Flat End Mill and Acrylic with 3.175 mm Single Flute Flat End Mill. Depending on the CNC bits and materials used, the cutting speed might vary.

We are here to help

Please feel free to contact us if you have any questions or concerns! info@snapmaker.com

Basic Information

Standard 3D Printing Function

Independent Dual Extrusion (IDEX)

Single Extrusion

Dual Extrusion

Standard Laser Function

-

1600mW

10W

Standard CNC Function

-

50W

200W

Standard Enclosure

Equipped

Equipped

Equipped

Work Area

(W × D × H)

Default Mode & Backup Mode:

300mm x 200mm x 200mm

Copy Mode:

160mm x 200mm x 200mm

Mirror Mode:

150mm x 200mm x 200mm

Single Extrusion Module:

230 × 250 × 235 mm (A250T)

320 × 350 × 330 mm (A350T)

Dual Extrusion:

350 × 400 × 400 mm

Enclosure Dimensions

(W × D × H)

539 × 401 × 464 mm

624 × 530 × 507 mm (A250T)

820 × 626 × 603 mm (A350T)

665 × 943 × 705 mm

Maximum Printing Speed

350 mm/s

100 mm/s

300 mm/s

Maximum Acceleration

10,000 mm/s2

1,000 mm/s2

2,000 mm/s2

Maximum Nozzle Temperature

300°C

275°C

300°C

Rated Power

400W

320W

350W + 400W

Software

Luban

Luban

Luban

Expandability

Enclosure

-

Equipped

Equipped

Quick-swap Design

-

× (Available Soon)

√

Motion System

Motor Driver Chip of Linear Module

TMC2209

TMC2209

TMC2209

X-axis Lead

40 mm

20 mm

40 mm

Y-axis Lead

40 mm

20 mm

40 mm

Z-axis Lead

2 mm

8 mm

8 mm

Transmission System

Industrial Linear Rail

Lead Screw

Embedded Steel Guiderail

3D Printing

Build Plate

PEI-coated Glass

Steel Plate with PC

Stickers on Both Sides

PEI-coated Glass

Supported Nozzle

Diameter

Standard:

0.4 mm Brass Nozzle ×2

Optional:

0.2 mm Brass Nozzle,

0.6 mm Brass Nozzle,

0.8 mm Brass Nozzle,

0.4 mm Hardened Nozzle

Standard:

0.4 mm Brass Nozzle

Standard:

0.4 mm Brass Nozzle ×2

Optional:

0.2 mm Brass Nozzle,

0.6 mm Brass Nozzle,

0.8 mm Brass Nozzle,

0.4 mm Hardened Nozzle

High-temperature Zone

×

×

260 mm × 260 mm

Zone Heating

×

×

√

Heating Speed of

Heated Bed

Heating up to

60°C in 4 min

Heating up to

60°C in 4 to 5 min

High-temperature Zone:

Heating up to 60°C in 2 to 3 min

The Whole Heated Zone:

Heating up to 60°C in 4 to 5 min

Maximum Temperature

of Heated Bed

100°C

100°C (A250T)

80°C (A350T)

High-temperature

Zone: 110°C

Outer Zone: 80°C

Supported Materials

PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, PA, PA-GF, PA-CF

PLA, ABS, PETG, TPU

PLA, ABS, PETG, TPU, PVA,

Breakaway PLA, HIPS,

PA-CF, PA-GF, ASA

Laser Engraving and Cutting

1600mW Laser Module

-

Equipped

Optional

10W Laser Module

-

Optional

Standard

Maximum

Engraving Speed

-

15 mm/s

100 mm/s

Maximum Cutting Depth

-

1.5 mm Paulownia

8 mm Paulownia

Standard Camera

-

No Wide Angle

Wide Angle

Supported

Engraving Materials

-

Basswood, Paulownia, Pinewood, Plywood, Bamboo, Leather, Fabric, Paper, Dark Acrylic (Blue excluded)

Basswood, Paulownia, Pinewood, Plywood, Beech, Walnut, Bamboo, MDF, Painted Metal, Copper Clad Laminate, Tinplate, Stainless Steel, Anodized Aluminum, Dark Glass, Slate, Ceramics, Jade, Marble, Shale, Leather, Fabric, Canvas, Corrugated Paper, Cardboard, Plastic, Dark Acrylic (Blue excluded)

Supported Cutting

Materials

-

Basswood, Paulownia, Pinewood, Plywood, Paper, Dark Acrylic (Blue excluded)

Basswood, Paulownia, Pinewood, Plywood, Beech, Walnut, Bamboo, MDF, Leather, Fabric, Canvas, Corrugated Paper, Cardboard, Plastic, Dark Acrylic (Blue excluded)

Work Area (W × D)

-

230 × 250 mm (A250T)

320 × 350 mm (A350T)

400 × 400 mm

CNC Carving

50W CNC Module

-

Equipped

Optional

200W CNC Module

-

Incompatible

Equipped

Maximum Spindle Speed

-

12,000 RPM

18,000 RPM

Maximum Work Speed[1]

-

Beech: 16 mm/s

Acrylic: 10 mm/s

Beech: 50 mm/s

Acrylic: 33 mm/s

Maximum Stepdown

-

Beech: 1 mm

Acrylic: 0.5 mm

Beech: 2 mm

Acrylic: 1 mm

Supported Materials

-

Hardwood (Beech, Walnut), Softwood, Acrylic, PCB, Carbon Fiber, Jade

Hardwood (Beech, Walnut), Softwood, HDF, MDF, Plywood, Jade, Carbon Fiber, Acrylic, Epoxy Tooling Board, PCB

Work Area (W × D × H)

-

230 × 250 × 180 mm (A250T)

320 × 350 × 275 mm (A350T)

400 mm × 400 mm × 400 mm

[1] The data is obtained by cutting beech with 3.175 mm Double Flute Flat End Mill and Acrylic with 3.175 mm Single Flute Flat End Mill. Depending on the CNC bits and materials used, the cutting speed might vary.

We are here to help

Please feel free to contact us if you have any questions or concerns! info@snapmaker.com

ORDER ISSUES

Delivery time & Express company.

Except pre-order products:

Delivery time:

Express company:

What payment methods do Snapmaker online store support?

Do I have to pay any extra fee?

It depends on the destination country.

For EU, AU, UK, CA customers: We have warehouses in these countries, so you don't need to pay any extra fee.

For US customers: You don't need to pay customs duty, but due to each state's policy, you may have to pay sales tax.

For customers in other countries: You need to handle the customs clearance and pay the taxes. If you don't have any experience in this, please consult your local customs department.

We will build more warehouses in the future and help our customers save more costs to get our machine.

When will I receive the tracking number?

Normally, your order will be available for delivery within 1 after you make the payment. Once your order is shipped out, the system will automatically send you the tracking number by email. The tracking number will be delayed during holidays, or when your order is out of stock.

Where will the product be shipped from?

PRODUCT & CASE

Can I change the machine model after placing an order?

What type of materials does the Snapmaker printer support?

3D printing

Laser Engraving

CNC Carving

Can you provide pictures of the case made by the Snapmaker printer?

RETURNS AND WARRANTY

Return and Refund ServiceReturn and Refund Service

- It is requested beyond seven (7) calendar days of receiving a Product.

- A Product sent to Snapmaker for Return & Refund Service does not include all original accessories and packaging or any item is not in new or like-new condition, i.e. with cracks, dents, or scratches.

- Legal proof of purchase, receipt, or invoice is not provided.

- Any fault or damage of the Product is caused by unauthorized use or modification of the Product, including exposure to moisture, entry of foreign bodies (water, oil, sand, etc.) or improper installation or operation.

- Product labels, serial numbers, etc. show signs of tampering or alteration.

- Damage is caused to the Product by uncontrollable external factors, including fire, floods, high winds, or lightning strikes.

- A Product is not delivered to the designated warehouse within seven (7) calendar days after Return & Refund Service confirmation is sent from Snapmaker.

- Other circumstances stated in this policy.

Repair Service

This warranty does not apply to and therefore not cover

- Any other parts except for the Warranted Parts;

- Any defect or damage caused by failure to follow instructions in the Quick Start Guides and online Manuals, including but not limited to inappropriate, incorrect or improper use, installation, maintenance, operation, and cleaning;

- Any defect or damage caused by an accident, including but not limited to natural calamities such as fire hazard, and human causes such as falling off, collision and soaking in water;

- Any defect or damage caused by the use of third party materials, accessories or software, etc.;

- Normal wear and tear.

The following actions will void this warranty

- Any modification made to any hardware or firmware of the Product;

- Abuse, misuse or improper storage of the Product;

- Use the Product for any illegal purposes;

- Serviced by distributors other than Snapmaker or an authorized Snapmaker distributor;

- Use non-supported, unapproved or improper filament or materials with the Product;

- Disassemble or repair without authorization by Snapmaker or the Distributor.

Snapmaker’s Limited Warranty

Snapmaker Grants a limited warranty on the major modules of the Snapmaker 3-in-1 3D Printer series product (“Product”) purchased from Snapmaker or a Distributor authorized by Snapmaker according to the terms and conditions stated below.

The warranty starts from the date of delivery to an end-customer for the first time, as evidenced by the original customer’s purchase invoice. Only the original purchaser is entitled to claim a warranty.

| Product | Warranted Parts |

| Snapmaker Original | Controller |

| Heated Bed | |

| Printing module (Nozzle excluded) | |

| Laser module | |

| CNC module | |

| Linear module | |

| Touchscreen | |

| Power Adapter | |

| Snapmaker Original Add-ons | Enclosure for Snapmaker Original |

| Z-Axis Extension Module for Snapmaker Original | |

| 1600mW laser module for Snapmaker Original | |

| Snapmaker 2.0 (A150, A250, A350) | Controller |

| Heated Bed (Printing sheet excluded) | |

| Printing module (Nozzle excluded) | |

| Laser module | |

| CNC module | |

| Linear module | |

| Touchscreen | |

| Power Module | |

| Converter | |

| Snapmaker 2.0 Add-ons | Enclosure for Snapmaker 2.0 |

| Snapmaker 2.0 Rotary Module | |

| Emergency Stop Button | |

| Air Purifier (Filter Cartridge excluded) | |

| CAN Hub | |

|

Snapmaker 2.0 Bundle (EU customer only) | Snapmaker 2.0 |

| Enclosure for Snapmaker 2.0 |

Note: Parts that are replaced under the Warranty also fall under their original warranty duration and do not restart.

Warranty periods

Warranty periods for the EU countries and Non-EU countries.

- 2-year warranty for the customers from the EU countries

- 1-year warranty for the customers from the Non-EU countries

More About Snapmaker 3D Printer

What is the Fastest 3D Printer?

3D printing can take quite a bit of time; depending on the size and complexity of the project you're printing, you can expect it to take between hours and days to complete. While this might seem like a long time, just take a moment to think about what 3D printers are able to accomplish. There is also good news about these fantastic machines, advances are being made to make them faster and easier to use.

Fast, Accurate, and Easy to Use

If you're looking for the fastest 3D printer, look no further than the Snapmaker Artisan 3-in-1 3D Printer with Enclosure. It's designed to be precise, so everything you make is accurate. Quick Swap technology makes switching fast and easy; it takes less than one minute. This well-made machine is loaded with the features you're looking for, and does the job faster than the rest. This high quality machine is made to provide you with precise cuts in a sturdy machine that can handle intricate cuts while remaining stable even during fast cuttings.

3D printing is becoming more common as more people start buying them for both personal and professional use. It makes sense to choose one of the best and fastest 3D printers available. This printer is perfect for creating prototypes, home decor items, toys, and more. Have fun using the fastest 3D printer around. Advances in 3d printing technology have made this the perfect time to buy your own 3D printer.

What is the Highest Precision 3D Printer?

When it comes to 3D printing, precision is vital. The Snapmaker Artisan 3-in-1 3D Printer with Enclosure is the printer for you if having a high precision 3D printer is your goal. This high end 3D printer is loaded with features that will help make your 3D printing experience a great one.

Why is This Machine so Precise?

Industrial-grade transmission technology in this machine ensures the precision you crave. This machine is well made with top-of- the-line materials to ensure not only precision but durability as well. This printer will stand up to the demands of your busy workshop. Industrial 3D printers have a higher precision rate than other printers; this means greater accuracy for you. As everyone knows, accuracy is a must when it comes to 3D printing; without accuracy, your project will not work or look as you intended.

Better Features

No matter what you're creating, this high resolution 3D printer will provide you with an accurate and speedy finished project. The large work area allows for larger projects. Quick swap platforms allow you to switch between functions quickly, it will take just a minute. The all-metal die-cast base plate is larger in size than previous models of our 3D printers. The base plate is super sturdy to ensure it stays steady even during high-speed printing. It is.another aspect of this printer that ensures precision.

If you're looking for high-quality 3D printing the Snapmaker Artisan 3-in-1 3D printer with enclosure is for you. The precision, the speed, and the durability you want are all here in this one machine. The company has heard what you, the consumer, is looking for, and they put it all in this one superior machine; these high resolution 3D printers will meet and exceed your expectations.

Options to Fit Your Needs

The customized configuration lets you easily make your prototypes in a snap. This printer was designed with ease of operation in mind. From the large touch screen to the dual extension 3D printing module that allows for dissolvable materials, your comfort and enjoyment of this machine were at the forefront of the creators' minds. Being about to use dissolvable materials means less processing post-printing.

Whether you are looking for a high quality 3D printer for work or play, when you want the best, fastest, most precise printer, check out the Snapmaker Artisan 3-in-1 3D printer. It's made to exceed your expectations and take the stress out of 3D printing. Precision is just one of the excellent features of this fantastic machine; you'll find many reasons to love it.

Which 3D Printer Is Best for Commercial Use?

Choosing a 3D printer for commercial use does not have to be difficult. While it can seem overwhelming due to the various models on the market, you just have to know what to look for when you shop. You must shop according to features; some consumers shop according to cost, which only leads to problems. A less expensive printer is not necessarily inferior just as the most pricey does to signify superiority. Keep reading to learn more about the features to look for when determining which 3D printer commercial use compatible to choose.

Well-built to Last

An industrial metal 3D printer is needed for commercial use. These printers are well-made and do can the work you need the printer to do. Consider the Snapmaker Artisan 3-in-1 3D printer. This printer is all metal with a die-cast base plate. This gives users a durable machine that does superior work on your 3D printed objects.

The Features You Want

Know what features you want in your 3D printer. It's a good idea to make a mental list of what you plan to do with the printer and what features will help you meet your goal. For example, if you want to print miniatures, consider what features make a printer the best 3d printer for miniatures. Below are the best features to look for when you shop.

- Precision will help whether you are printing miniatures or oversized pieces.

- Quick swap technology so you are not wasting time switching things out. Quick Swap lets you get things switched out in just a minute.

- Large base plate to meet all of your 3d printing needs.

- The faster your printer works, the better; choose something fast. Printer technology keeps improving, today's printers are faster than those made just a year ago.

- A large touch screen gives you more room to work and create. Anything that makes life easier is a good feature and a large touchscreen does make life easier.

- Choose a printer that can remain stable even when printing at high speeds.

- Buy from a company that offers support. If you need help, it's nice to know that someone is there.

Now that you know what to look for, you're ready to begin shopping for your 3D printer for your commercial needs. Follow the above tips to find the perfect printer for your needs. Be sure to check out the Snapmaker Artisan 3-in-1 3D printer with enclosure; it does all of the above and more. The Artisan 3d printer was made to be user-friendly, while still being able to stand up to your busy days. Remember, the right printer can make your days easier.

ORDER ISSUES

Delivery time & Express company.

Except pre-order products:

Delivery time:

Express company:

What payment methods do Snapmaker online store support?

Do I have to pay any extra fee?

It depends on the destination country.For EU, US, AU, UK, CA customers: We have warehouses in these countries, so you don't need to pay any extra fee. For customers in other countries: You need to do the customs clearance and pay the taxes. If you don't have any experience in this, please consult your local customs department.We will build more warehouses in the future and help our customers save more costs to get our machine.

When will I receive the tracking number?

Normally, your order will be available for delivery within 1 after you make the payment. Once your order is shipped out, the system will automatically send you the tracking number by email. The tracking number will be delayed during holidays, or when your order is out of stock.

Where will the product be shipped from?

PRODUCT & CASE

Can I change the machine model after placing an order?

What type of materials does the Snapmaker printer support?

3D printing

Laser Engraving

CNC Carving

Can you provide pictures of the case made by the Snapmaker printer?

RETURNS AND WARRANTY

Return and Refund ServiceReturn and Refund Service

- It is requested beyond seven (7) calendar days of receiving a Product.

- A Product sent to Snapmaker for Return & Refund Service does not include all original accessories and packaging or any item is not in new or like-new condition, i.e. with cracks, dents, or scratches.

- Legal proof of purchase, receipt, or invoice is not provided.

- Any fault or damage of the Product is caused by unauthorized use or modification of the Product, including exposure to moisture, entry of foreign bodies (water, oil, sand, etc.) or improper installation or operation.

- Product labels, serial numbers, etc. show signs of tampering or alteration.

- Damage is caused to the Product by uncontrollable external factors, including fire, floods, high winds, or lightning strikes.

- A Product is not delivered to the designated warehouse within seven (7) calendar days after Return & Refund Service confirmation is sent from Snapmaker.

- Other circumstances stated in this policy.

Repair Service

This warranty does not apply to and therefore not cover

- Any other parts except for the Warranted Parts;

- Any defect or damage caused by failure to follow instructions in the Quick Start Guides and online Manuals, including but not limited to inappropriate, incorrect or improper use, installation, maintenance, operation, and cleaning;

- Any defect or damage caused by an accident, including but not limited to natural calamities such as fire hazard, and human causes such as falling off, collision and soaking in water;

- Any defect or damage caused by the use of third party materials, accessories or software, etc.;

- Normal wear and tear.

The following actions will void this warranty

- Any modification made to any hardware or firmware of the Product;

- Abuse, misuse or improper storage of the Product;

- Use the Product for any illegal purposes;

- Serviced by distributors other than Snapmaker or an authorized Snapmaker distributor;

- Use non-supported, unapproved or improper filament or materials with the Product;

- Disassemble or repair without authorization by Snapmaker or the Distributor.

Snapmaker’s Limited Warranty

Snapmaker Grants a limited warranty on the major modules of the Snapmaker 3-in-1 3D Printer series product (“Product”) purchased from Snapmaker or a Distributor authorized by Snapmaker according to the terms and conditions stated below.

The warranty starts from the date of delivery to an end-customer for the first time, as evidenced by the original customer’s purchase invoice. Only the original purchaser is entitled to claim a warranty.

| Product | Warranted Parts |

| Snapmaker Original | Controller |

| Heated Bed | |

| Printing module (Nozzle excluded) | |

| Laser module | |

| CNC module | |

| Linear module | |

| Touchscreen | |

| Power Adapter | |

| Snapmaker Original Add-ons | Enclosure for Snapmaker Original |

| Z-Axis Extension Module for Snapmaker Original | |

| 1600mW laser module for Snapmaker Original | |

| Snapmaker 2.0 (A150, A250, A350) | Controller |

| Heated Bed (Printing sheet excluded) | |

| Printing module (Nozzle excluded) | |

| Laser module | |

| CNC module | |

| Linear module | |

| Touchscreen | |

| Power Module | |

| Converter | |

| Snapmaker 2.0 Add-ons | Enclosure for Snapmaker 2.0 |

| Snapmaker 2.0 Rotary Module | |

| Emergency Stop Button | |

| Air Purifier (Filter Cartridge excluded) | |

| CAN Hub | |

|

Snapmaker 2.0 Bundle (EU customer only) | Snapmaker 2.0 |

| Enclosure for Snapmaker 2.0 |

Note: Parts that are replaced under the Warranty also fall under their original warranty duration and do not restart.

Warranty periods

Warranty periods for the EU countries and Non-EU countries.

- 2-year warranty for the customers from the EU countries

- 1-year warranty for the customers from the Non-EU countries

Reasons for having a 3D laser printer

Reasons for having a 3D laser printer

- Newly designed power module with intelligent fan speed adjustment.

- 1600mW laser cutting module with a built-in camera.

- CNC carving module with ER11 collet.

- Controller powered by Cortex-M4 processor.

- Magnetic Heated Bed with a removable print sheet for 3D printing.

- 5" Smart touchscreen (Android OS, Quad Core A7 CPU @ 1.1GHz).

- Newly designed linear modules.

- Newly designed 3D printing module.

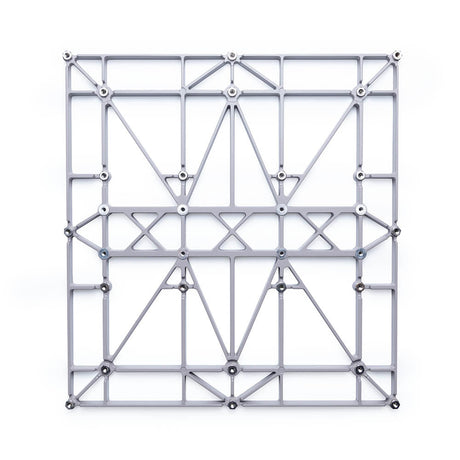

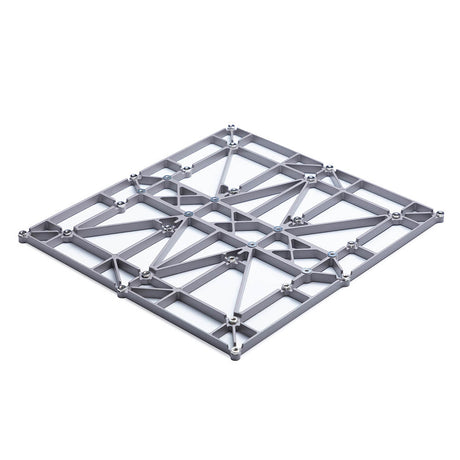

- Aluminum grid table for laser engraving and cutting.

- MDF board and clamp sets for CNC carving.

- Free 3-in-1 Software: Snapmaker luban.

- Materials include 1kg spool of PLA filament, two pcs of the laser material, and one pc of CNC material.

What software programs or tools are needed to design and prepare 3D models for printing, and are there any recommended programs for beginners?

Some popular programs for 3D modeling and design include:

1. Tinkercad: Tinkercad is a free, web-based program that offers basic 3D modeling tools and is great for beginners.

2. SketchUp: SketchUp is a user-friendly 3D modeling program that offers a free version for personal use.

3. Fusion 360: Fusion 360 is a professional-grade 3D modeling program that is free for students, educators, and hobbyists.

4. Blender: Blender is a powerful open-source 3D modeling program that is free to use and offers a wide range of features.

5. AutoCAD: AutoCAD is a professional-grade 3D modeling program that offers a free trial and is used widely in architecture, engineering, and product design.

Once a 3D model has been created, it must be prepared for printing using a slicing software, which converts the model into a series of 2D layers that can be printed by the 3D printer. Some popular slicing software programs include:

1. Cura: A free, open-source slicing software that is compatible with a wide range of 3D printers.

2. Simplify3D: A professional-grade slicing software that offers advanced features and is compatible with a wide range of 3D printers.

3. PrusaSlicer: A free, open-source slicing software that is optimized for Prusa 3D printers but is also compatible with other printers.

4. Snapmaker Luban: A free, open-source software that offers a wide range of features for 3D printing, laser engraving, and CNC carving. It's a versatile and user-friendly software program that is well-suited for both beginners and advanced users of the Snapmaker 3-in-1 3D printer.

For beginners, it is recommended to start with a simple program like Tinkercad and work up to more advanced programs like Fusion 360 or AutoCAD. Many of these programs offer tutorials and online resources to help users get started.

How do different types of 3D printing technology, such as FDM, SLA, and SLS, work and what are their advantages and disadvantages?

1. Fused Deposition Modeling (FDM):

FDM is a popular 3D printing technology that works by extruding melted filament through a nozzle to create a 3D object layer by layer. The advantages of FDM include:

- Affordable and widely available

- Can print with a variety of materials, including PLA, ABS, and PETG

- Easy to use and maintain

- Can create large objects with a build volume up to 1000 mm or more

The disadvantages of FDM include:

- Limited printing resolution compared to other technologies

- Requires support structures for overhangs and intricate designs

- Finished prints may require post-processing to remove support structures and achieve a smooth surface

2. Stereolithography (SLA):

SLA is a type of 3D printing technology that uses a liquid resin that is cured by a UV laser to create a 3D object layer by layer. The advantages of SLA include:

- High printing resolution, capable of producing very fine details and intricate designs

- Smooth surface finish without requiring post-processing

- Can print with a variety of materials, including clear and flexible resins

The disadvantages of SLA include:

- Limited build volume compared to other technologies

- Higher cost compared to FDM printers and resins

- Resin can be messy to handle and require special storage and handling precautions

3. Selective Laser Sintering (SLS):

SLS is a type of 3D printing technology that uses a laser to sinter (fuse) powdered material together to create a 3D object layer by layer. The advantages of SLS include:

- High printing resolution and capable of producing complex geometries

- Can print with a variety of materials, including nylon, TPU, and metal powders

- Does not require support structures as the unsintered powder supports the object during printing

The disadvantages of SLS include:

- Higher cost compared to FDM and SLA technologies

- Limited printing speed compared to FDM

- Requires special handling and post-processing to remove unsintered powder

In summary, each type of 3D printing technology has its own advantages and disadvantages, and the choice of which technology to use depends on the specific needs of the project.

How do you troubleshoot common 3D printing issues such as clogging, warping, or adhesion problems?

3D printing issues can arise due to various reasons such as improper settings, incorrect filament, or mechanical issues. Here are some common 3D printing issues and troubleshooting tips:

1. Clogging:

Clogging occurs when the filament gets stuck in the hot end, preventing it from extruding. This can happen due to various reasons such as a worn-out nozzle, a dirty extruder, or incorrect temperature settings. To troubleshoot clogging:

- Clean the nozzle and extruder with a cleaning filament or by manually removing any debris or clogs.

- Increase the nozzle temperature slightly to help clear any obstructions.

- Replace the nozzle if it's worn out or damaged.

2. Warping:

Warping occurs when the edges of the printed object start to curl up or detach from the print bed. This can happen due to uneven cooling, incorrect bed temperature, or poor bed adhesion. To troubleshoot warping:

- Ensure that the print bed is leveled properly and the nozzle is at the correct distance from the bed.

- Increase the bed temperature and ensure that the bed is clean and free of debris.

- Use a heated bed or add a bed adhesive such as a glue stick, hairspray, or painter's tape to improve bed adhesion.

3. Adhesion problems:

Adhesion problems occur when the filament does not stick properly to the print bed or detaches during printing. This can happen due to poor bed adhesion, incorrect temperature settings, or incorrect print bed leveling. To troubleshoot adhesion problems:

- Ensure that the print bed is clean and free of debris.

- Use a bed adhesive such as a glue stick, hairspray, or painter's tape to improve bed adhesion.

- Increase the bed temperature and ensure that the nozzle is at the correct distance from the bed.

- Adjust the print bed leveling to ensure that the nozzle is at the correct distance from the bed.

In summary, troubleshooting 3D printing issues requires a systematic approach to isolate the root cause of the problem. It is important to regularly maintain and calibrate your 3D printer to prevent issues from occurring in the first place.

What are the environmental impacts of 3D printing, such as waste generation and energy usage, and are there any sustainable practices that can be implemented?

3D printing has the potential to reduce waste and energy usage compared to traditional manufacturing methods, but it still has some environmental impacts that need to be considered.

Waste Generation:

3D printing can generate waste in the form of support structures, failed prints, and excess filament. To reduce waste, it is important to:

- Design 3D models with minimal support structures and waste in mind.

- Use biodegradable and compostable filaments such as PLA instead of non-biodegradable materials like ABS.

- Recycle and properly dispose of failed prints and excess filament.

Energy Usage:

3D printing consumes energy, and the amount of energy used depends on the printer and the printing process. To reduce energy usage, it is important to:

- Use energy-efficient printers that consume less power.

- Print at lower temperatures and slower speeds to reduce energy consumption.

- Use renewable energy sources such as solar or wind power to power the printer.

In addition, sustainable practices can be implemented to reduce the environmental impact of 3D printing, such as:

- Sharing 3D printer resources through community spaces, makerspaces, or libraries to reduce the need for individuals to own their own printers.

- Using recycled or reclaimed materials for printing.

- Repurposing or recycling failed prints and support structures.

In summary, while 3D printing has the potential to reduce waste and energy usage compared to traditional manufacturing methods, it still has some environmental impacts that need to be considered. By implementing sustainable practices and using environmentally friendly materials, 3D printing can become a more sustainable technology.

![[REPLACEMENT] DOUBLE-SIDED PEI GLASS PLATE FOR SNAPMAKER J1/J1S](http://eu.snapmaker.com/cdn/shop/products/J1__1_1000_1000_b5408d1b-36b8-4214-a7e8-48cd1596178a.png?v=1667914597&width=460)

![[REPLACEMENT] DOUBLE-SIDED PEI GLASS PLATE FOR SNAPMAKER J1/J1S](http://eu.snapmaker.com/cdn/shop/products/J1__2_1000_1000_356d2fa6-31d4-4e94-b6a1-bc6419b48704.png?v=1667914597&width=460)