Product Overview

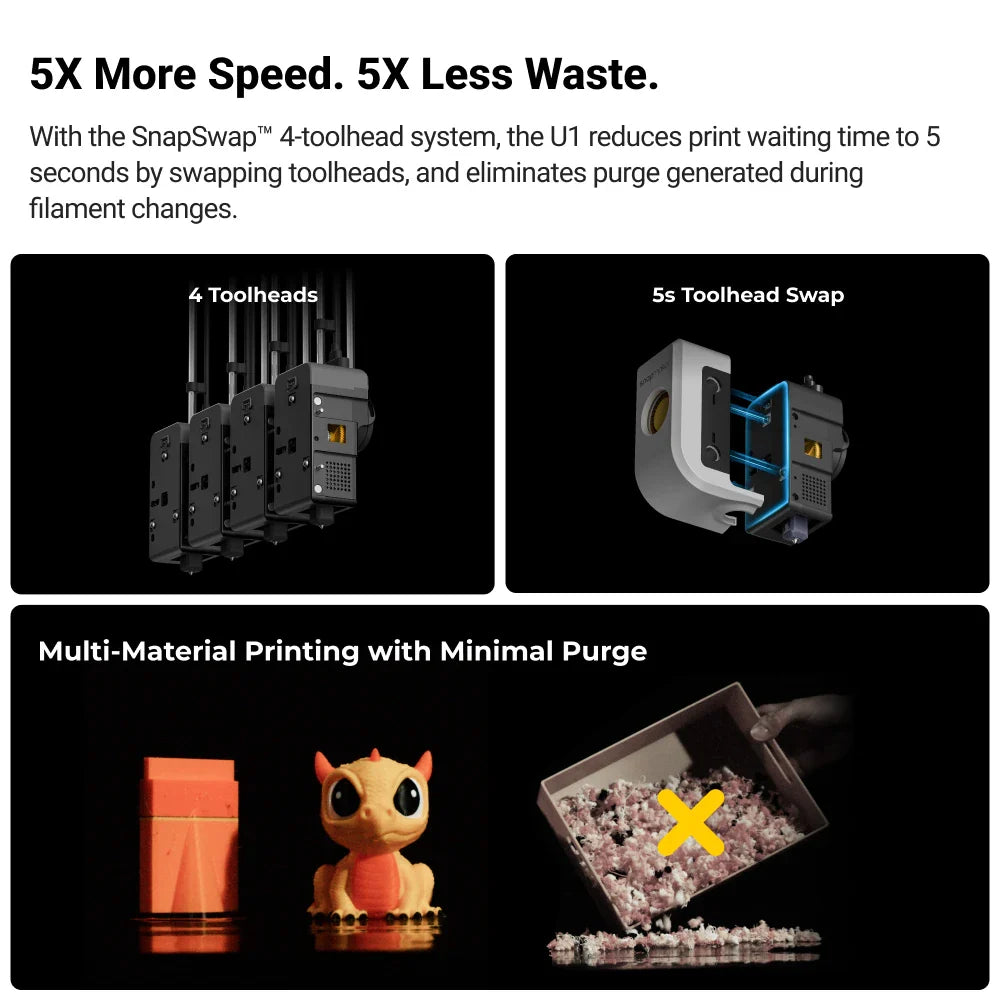

• Smooth Printing with 5X More Speed and 5X Less Waste

• SnapSwap™ 4-Toolhead System with 5s Tool Change

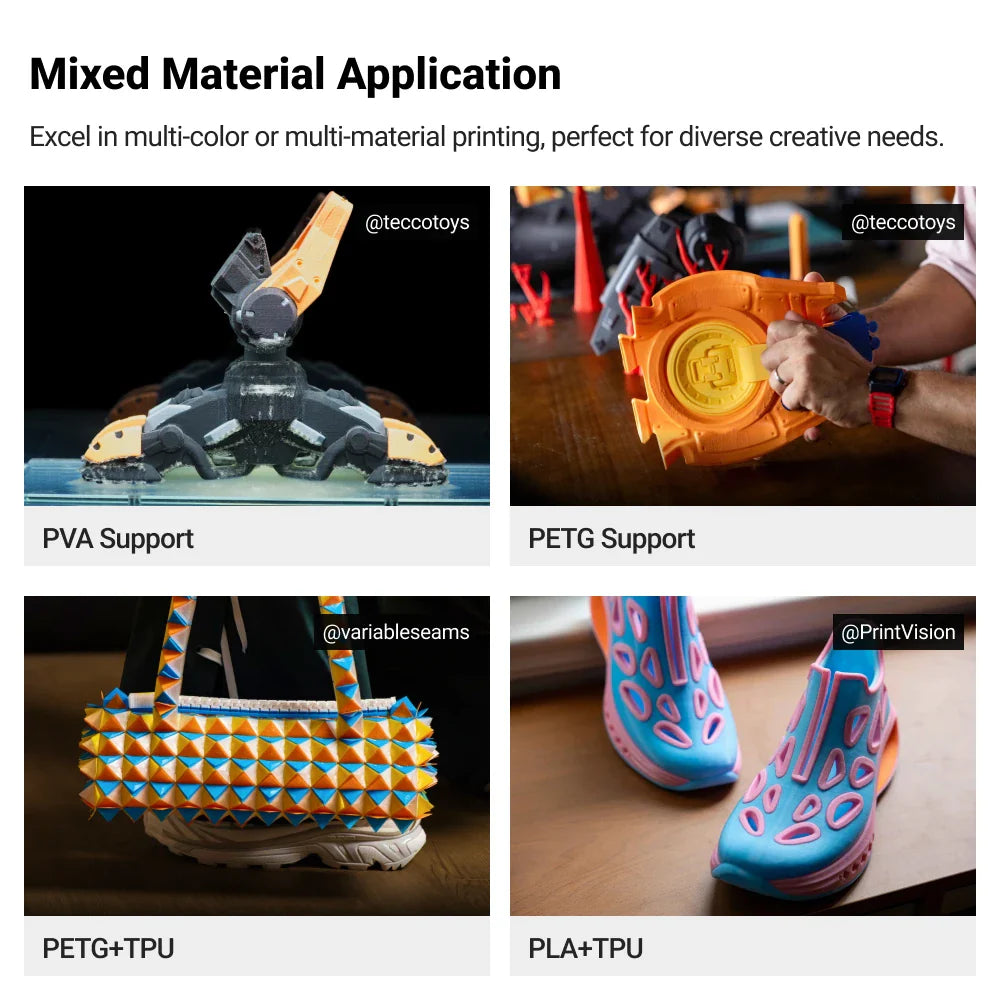

• Multi-Color & Multi-Material Printing

• 4 Toolheads Work As One

• Auto Filament Loading

• 500 mm/s Max Speed, Up to 20,000 mm/s² Acceleration

• 270*270*270mm³ Build Volume

Snapmaker U1 3D Printer

Featured RFID Filament

SnapSpeed PLA Filament Bundle (RFID)

€64,00 €109,00

Matte PLA Filament (1kg)

€22,90 €23,99

SnapSpeed PLA Filament (1kg)

€22,90 €26,99

Featured Add-ons & Accessories

Top Cover for Snapmaker U1

€159,00 €269,00

Hot End for Snapmaker U1

€54,00 €89,00

SnapDryer Bundle

€129,00 €179,00

PEI Steel Sheet for Snapmaker U1

€27,99 €39,99

Graphic Effect Steel Plate for Snapmaker U1

€24,99 €33,99

Nozzle Cleaning Brushes & Parking Pads Kit for Snapmaker U1

€4,99

Hot End Silicone Sock 4-Pack for Snapmaker U1

€4,99

Payment methods

Shipping & Tax Information

Shipping & Tax Information

€50 shipping fee per U1.

Prices include VAT.

- Features

- Specification & Parts

Frequently Asked Questions

1. Does Snapmaker support trade-in?

Currently, Snapmaker does not offer a trade-in option. However, we ensure peace of mind with a limited warranty covering major modules of Snapmaker 3D Printer purchased directly from us or through an authorized distributor. For detailed information and to enhance your shopping experience, please review our warranty policy.

2. If I purchase the Artisan 3-in-1 3D Printer(Premium), do I also need to purchase the Boosted Exhaust Fan?

There's no need to buy a separate exhaust fan; the Artisan 3-in-1 3D Printer (Premium) already includes a Boosted Exhaust Fan. With a powerful airflow capacity of 95CFM, this fan effectively removes smoke and fumes, ensuring a cleaner and safer printing environment.

3. Is a quick swap toolhead plate included with the purchase of the Artisan 3-in-1 3D Printer (Premium)?

Yes, the Artisan 3-in-1 3D Printer (Premium) comes equipped with the quick swap toolhead plate, which allows for adjustable tightness between the toolhead bracket and the toolhead plate for seamless operation and customization.

4. How are Snapmaker Artisan and Snapmaker 2.0 compatible with other modules and addons?

5. Should I choose the Artisan 3-in-1 3D Printer or three separate machines for 3D printing, CNC milling, and laser engraving?

Opting for the Snapmaker Artisan offers significant benefits if you prioritize a streamlined workflow and space efficiency. This all-in-one machine combines advanced 3D printing, CNC milling, and laser engraving in a single, compact unit. Its modular design allows for quick and easy switching between functions, maximizing both time and space. Equipped with high-precision components like a dual-nozzle printer and a powerful laser module, the Artisan ensures top-quality outputs across various tasks, making it an excellent choice for those seeking versatility without the spatial demands of multiple devices.

6. What safety mechanisms are in place during laser operations on the Artisan 3-in-1 3D Printer?

We embedded a door-detection sensor in the Enclosure, a gyro sensor and temperature sensor in the Laser module, Emergency Stop Button in the Integrated Controller. Your safety is in good hands.

7. How does the dual extruder function enhance 3D printing on the Snapmaker Artisan?

The dual extruder allows for printing with two different colors or materials simultaneously, ideal for creating complex models with support structures or multi-colored objects.

Specifications

General

Dimensions

584mm × 499mm × 730mm

Build Volume

270mm × 270mm × 270mm

Weight

18.2kg

Printing Properties

Printing Technology

Fused Deposition Modeling

Build Volume

584mm × 499mm × 730mm

Max Toolhead Speed

500mm/s

Max Acceleration Speed

20,000mm/s²

Toolhead

Toolheads Included

Fused Deposition Modeling

Max Flow for Hot End

584mm × 499mm × 730mm

Nozzle

18.2kg

Max Nozzle Temperature

18.2kg

Nozzle

18.2kg

Nozzle

18.2kg

Nozzle

18.2kg

- Features

- Specification & Parts

Meet Snapmaker U1

Make More, Waste Less

Perspectives from Pros

Creative Vibes, Uplifted by U1

Whether you're bonding over colorful creations at home, building your ultimate hobby hub, or adding a clever twist to your everyday style, the U1 makes it all effortless and fun.

- Home Use & Toys

- Hobby & DIY

- Fashion & Art

Switch Filaments in 5 Seconds with SnapSwap™

Most printers rely on filament changers to switch between colors or materials, spending more time purging than actually printing. With four toolheads preloaded and pre-heated with their own filaments, the SnapSwap™ system lets the U1 switch by simply swapping the toolheads, cutting your wait time from approximately two minutes to only five seconds[2].

Switch Filaments in 5 Seconds with SnapSwap™

Most printers rely on filament changers to switch between colors or materials, spending more time purging than actually printing. With four toolheads preloaded and pre-heated with their own filaments, the SnapSwap™ system lets the U1 switch by simply swapping the toolheads, cutting your wait time from approximately two minutes to only five seconds[2].

No More Purging for Color Change

Filament-changing printers "purge" by wasting perfectly good filament—pushing one color through the nozzle until the last trace of the old one is gone. The U1 doesn't play that game. It only purges the tiny amount of filament that's actually degraded by the time a new print job begins, or during flow-rate calibration, cutting waste by up to 80%[3] on every print.

Rock-Solid & Precise Locks

The U1 uses steel-ball kinematic couplings to click each print heat into perfect position, then locks it securely—no screws, no magnets, no extra motors. Locked fast, rock solid, tested over 1,000,000 swaps with zero failures.

No More Purging for Color Change

Filament-changing printers "purge" by wasting perfectly good filament—pushing one color through the nozzle until the last trace of the old one is gone. The U1 doesn't play that game. It only purges the tiny amount of filament that's actually degraded by the time a new print job begins, or during flow-rate calibration, cutting waste by up to 80%[3] on every print.

Rock-Solid & Precise Locks

The U1 uses steel-ball kinematic couplings to click each print heat into perfect position, then locks it securely—no screws, no magnets, no extra motors. Locked fast, rock solid, tested over 1,000,000 swaps with zero failures.

Less Waste Means Serious Savings

So. Much. Waste. On other 3D printers, printing a multi-color model leaves behind a mountain of garbage—often wasting 3 or 4 times more material than what ends up in the actual model! U1 avoids the waste with smart tool swapping, saving filament, saving money, and even saving the environment.

How Much Can You Save in a Year?

* “Others” refers to 3D printers that use a filament changer to swap materials.

* Based on PLA filament at an average cost of $15/kg, with a printing frequency of one piece per week.

Pick Your Material Pairs

With four independent extruders, the U1 lets you mix and match materials freely, giving each part its own function, or making support removal a breeze with low-adhesion combos.

Mix Materials for Easy-to-Remove Supports

- PETG Support

- PVA Support

With 4 toolheads, U1 prints stable PETG components to support your creation safely, avoiding mid-print warping. These supports are easy to detach without damage, so you can skip tedious prying and keep your finished prints intact.

PVA is costly but necessary for some creations. U1's 4-toolhead system minimizes purges to little or zero, so you can pair PVA with other materials freely, reduce waste greatly, and save money dramatically!

Blend Rigid and Flexible Materials

- PETG+TPU

- PLA+TPU

With 4 individual extruders, you can match flexible TPU and rigid PETG together, print more creative artwork such as a 3D printed hand bag.

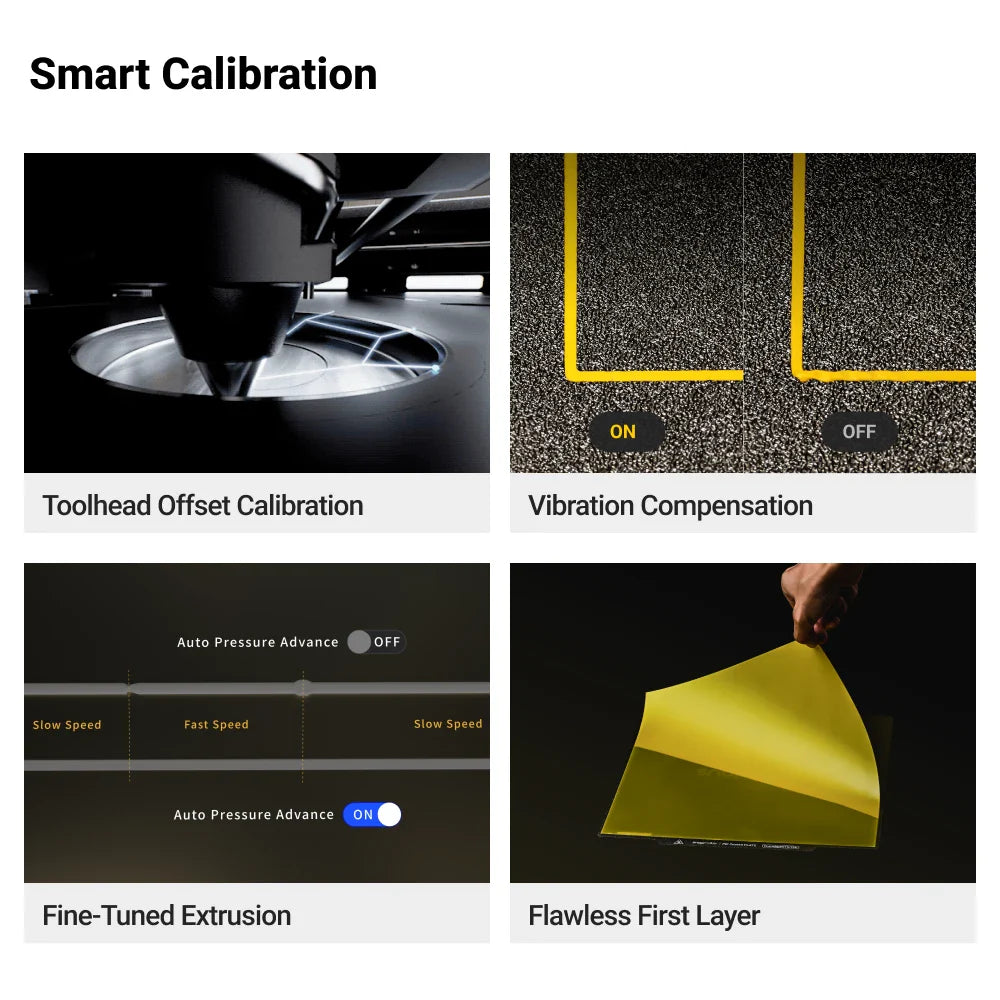

Smooth Print Starts with Smart Calibration

With four toolheads working at high speed, precision isn’t optional—it’s built in. The U1's compensation algorithms lock every toolhead in sync, dampen vibrations, dial in extrusion, and level out the build surface, so you get the smooth, dimensionally accurate results you’d expect from a top-tier single-head printer.

Toolhead Offset Calibration

U1 automatically aligns each toolhead with the main nozzle, holding offset under 0.04mm[4] to ensure sharp prints without vertical shifts.

Toolhead Offset Calibration

The U1 automatically aligns XYZ offsets between multiple toolheads, keeping offsets within 0.04mm[5] for sharp prints without vertical shifts.

Vibration Compensation for Consistent Prints

Input Shaping, aided by a precision accelerometer sensor, reduces vibrations caused by rapid directional changes by pre-processing movement commands to cancel out resonant frequencies. By adjusting acceleration profiles and introducing calculated delays, it prevents surface artifacts like ghosting or ripples, allowing the U1 to deliver clean edges, smooth walls, and sharp details even at high speeds.

Vibration Compensation for Consistent Prints

Input Shaping, aided by a precision accelerometer sensor, reduces vibrations caused by rapid directional changes by pre-processing movement commands to cancel out resonant frequencies. By adjusting acceleration profiles and introducing calculated delays, it prevents surface artifacts like ghosting or ripples, allowing the U1 to deliver clean edges, smooth walls, and sharp details even at high speeds.

Fine-tuned Extrusion for Exquisite Details

The U1 uses Pressure Advance to stay ahead of flow delays, especially during quick moves or sharp corners. It tweaks extrusion timing based on motion changes, so filament flows smoothly even when speeds shift. That means fewer blobs, less thinning, and crisp, consistent detail.

Fine-tuned Extrusion for Exquisite Details

U1 uses pressure advancThe U1 uses Pressure Advance to stay ahead of flow delays, especially during quick moves or sharp corners. It tweaks extrusion timing based on motion changes, so filament flows smoothly even when speeds shift. That means fewer blobs, less thinning, and crisp, consistent detail.

The First Layer Matters Too

The automatic mesh bed leveling delivers a flat, grippy first layer, setting the stage for every print.

The First Layer Matters Too

The automatic mesh bed leveling delivers a flat, grippy first layer, setting the stage for every print.

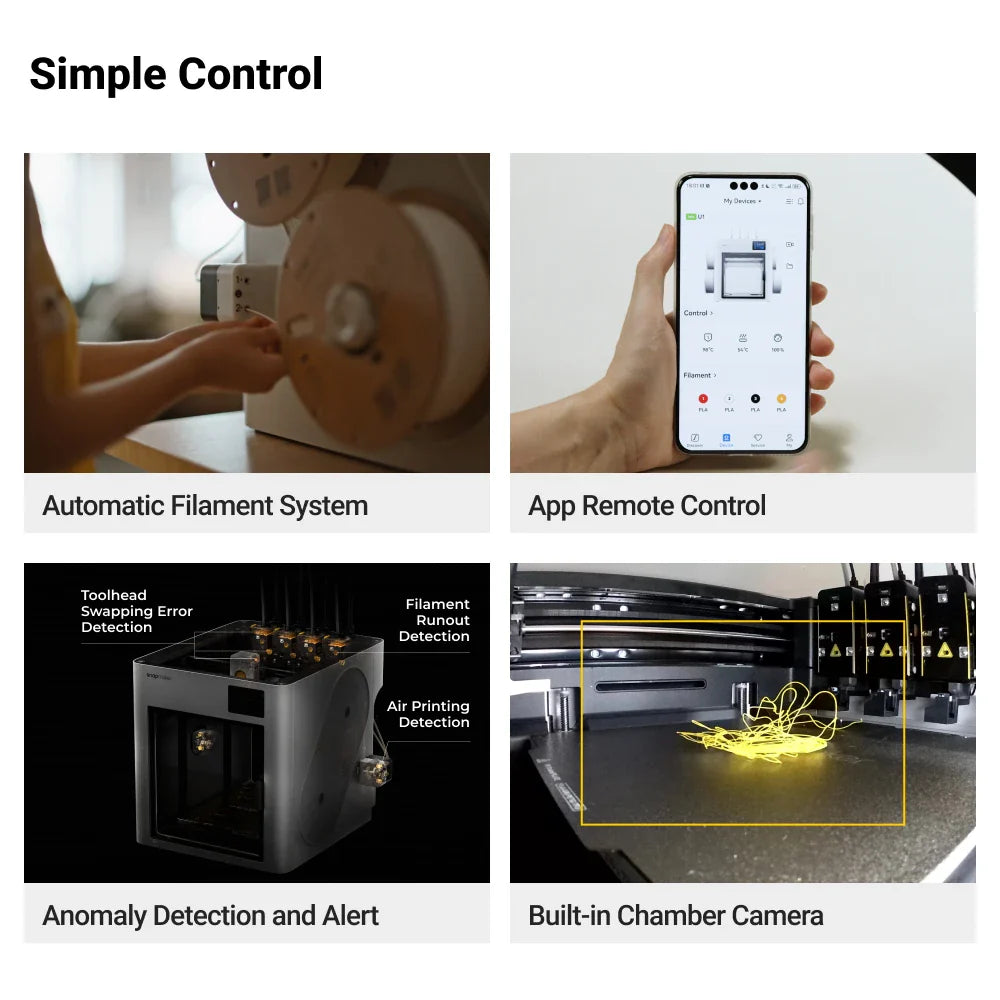

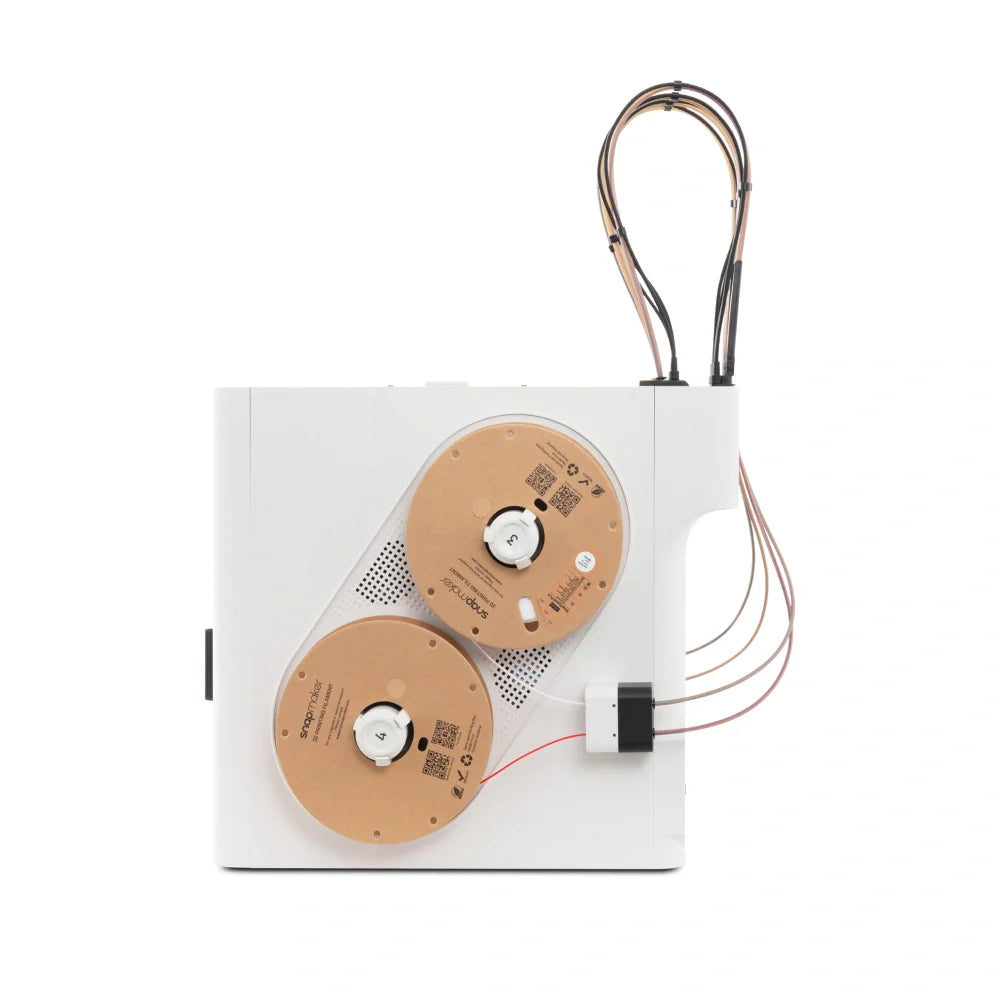

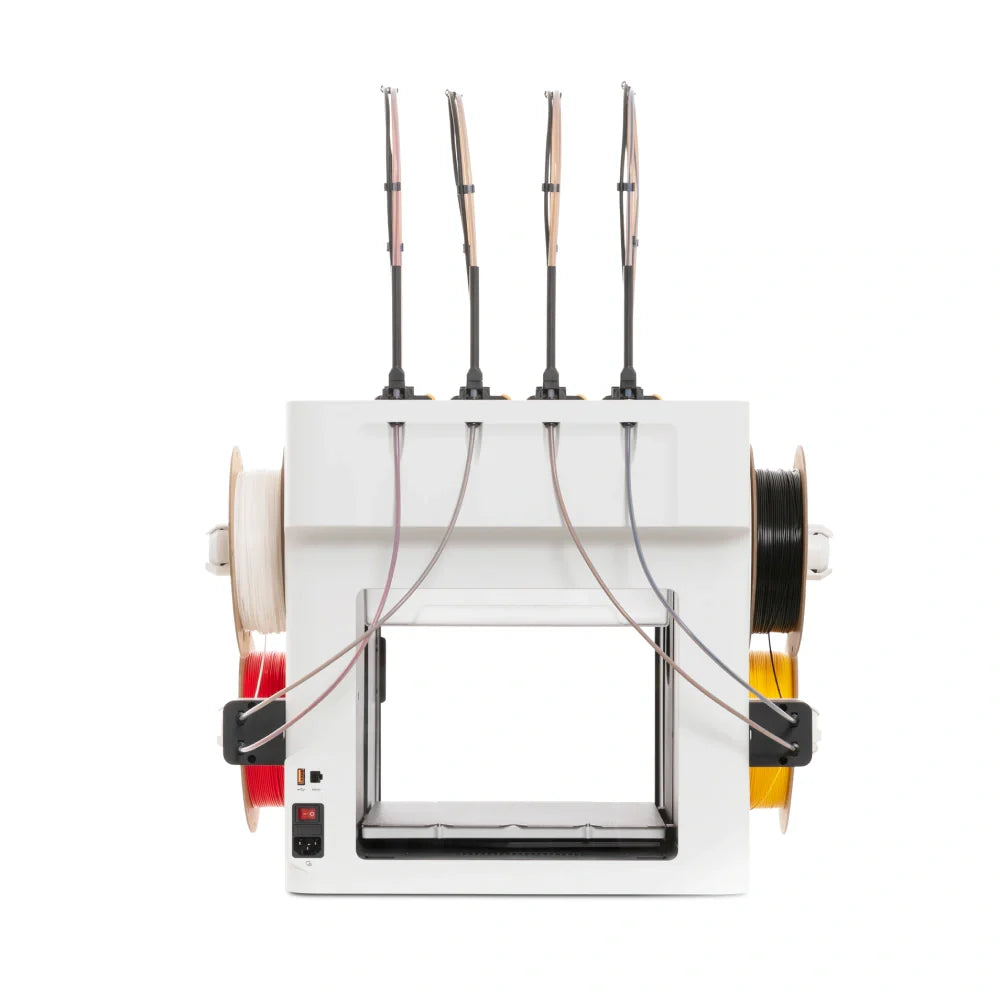

Effortless Filament Management

The U1 comes equipped with a super-compact automatic filament system that holds up to four spools on standby. It handles everything from filament detection and loading, so you can print in vivid color, hassle-free.

- Auto-loading

- Backup Mode

- RFID Recognition

Auto-loading

No more threading, fiddling, or guesswork. Just hang your filament and let it roll.

Backup Mode

When Backup Mode is on, U1 automatically switches to a matching spool when one runs out, so you'll never stress over what to do with those almost-empty rolls.

RFID Recognition

U1 uses RFID to detect specs like color, type, and more for Snapmaker official filaments, no need to type anything in.

Manage Your Prints with Ease

Snapmaker Orca builds on Orca Slicer’s powerful engine and adds engineer-tested profiles for official materials and machine models. Paired with the Snapmaker App, you can start, monitor, and control your prints from anywhere—and even capture 2. time-lapse videos to replay your creation in motion. Easy print management is right at your fingertips.

- Snapmaker APP

- Snapmaker Orca

- 3.5-inch Touchscreen

Anomaly Detection and Alert

With a mix of over a dozen sensors and precision mechanics, the U1 automatically spots issues and guides you through quick fixes, ensuring smooth, successful prints every time.

Capture the Highlights, Skip the Messes

The built-in chamber camera isn’t just for time-lapses. Starting with an OTA firmware update planned for December 2025 [5], its AI will detect spaghetti and workspace obstructions and alert you in Snapmaker Orca or the app, helping you avoid wasted time and material.

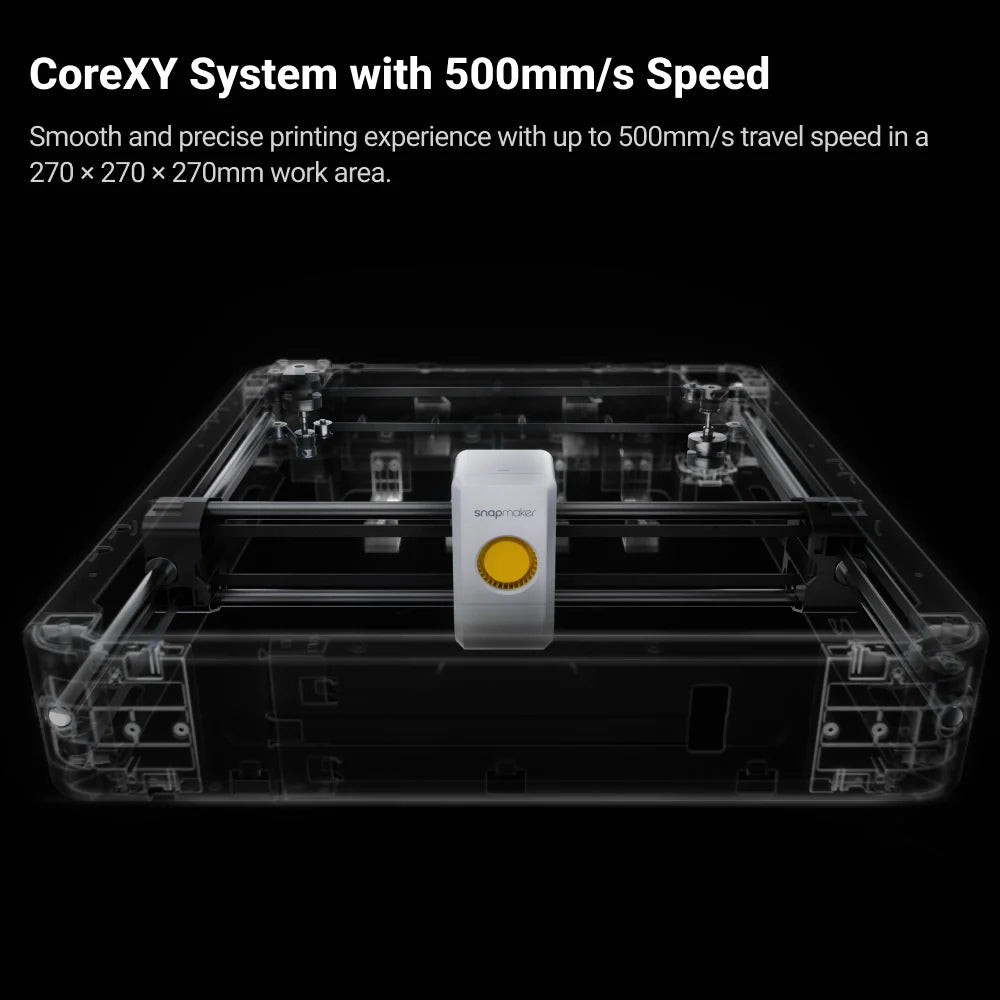

CoreXY System with 500mm/s Speed

The U1 is built on a CoreXY motion system with lightweight, rigid carbon fiber X-axis rails, delivering speeds of up to 500mm/s and maintaining long-term precision across a 270 × 270 × 270mm work area.

How the U1 Is Built and Tested

Snapmaker machines are built for excellence, as our longtime users know very well. From careful assembly to rigorous lab testing, each unit is crafted for the reliability, consistency, and creative freedom you've come to expect.

How the U1 Is Built and Tested

Snapmaker machines are built for excellence, as our longtime users know very well. From careful assembly to rigorous lab testing, each unit is crafted for the reliability, consistency, and creative freedom you've come to expect.

Specifications

General

Dimensions2

584mm × 499mm × 730mm

Weight

18.2kg

Printing Properties

Printing Technology

Fused Deposition Modeling

Build Volume

270mm × 270mm × 270mm

Max Toolhead Speed

500mm/s

Max Acceleration Speed

20,000mm/s²

Toolhead

Toolheads Included

4

Max Flow for Hot End

32mm³/s[6]

Nozzle

Stainless Steel

Max Nozzle Temperature

300°C

Nozzle Diameter

0.4mm

Filament Diameter

1.75mm

Part Cooling

Main & Auxiliary Part Cooling Fans

Heated Bed

Build Plate

Flexible Steel Sheet with PEI Surface

Max Heated Bed Temperature

100°C

Supported Filament Type

Basic Material Compatibility

PLA, PETG, TPU, PVA, PCTG

With Optional Top Cover

PLA, PETG, TPU, PVA, PET, ABS, ASA, PA, PC

With Top Cover & Hardened Steel Nozzle

PLA, PETG, TPU, PVA, PET, ABS, ASA, PA, PC, Carbon-fiber-reinforced Polymer, Glass-fiber-reinforced Polymer

Electronics

Touchscreen

3.5-inch 320 × 480 Touchscreen

Data Transmission Methods

Wi-Fi (IEEE802.11b/g/n Standards, 2.4GHz), USB Flash Drive

Storage

26 GB eMMC

Live View Camera

2 Megapixel Built-in Chamber Camera

Max Input Power

1150 W (220-240 V~), 400 W (100-120V~)

Max Input Current

6 A(220-240V~), 4 A(100-120 V~)

Auto-calibration

Heated Bed Leveling

Mesh Bed Leveling

Active Vibration Control

Accelerometer & Input Shaping Calibration

Automatic Flow Compensation

Pressure Advance Calibration

Automatic Toolhead Offset Calibration

Coordinate Measuring Calibration

Automatic Filament System

Auto-feed

Supported

Backup Mode

Supported

Filament RFID Recognition

Supported

Failure Detection

Air Printing Detection

Supported

Filament Run Out Detection

Supported

Power Loss Recovery

Supported

Anomaly Detection

Toolhead Swap Error Detection

Supported

Build Plate Presence Detection

Supported

Build Plate Obstruction Detection

Supported

Software

Supported Slicer

Snapmaker Orca, Orcaslicer

APP

Snapmaker APP

Operating System

Software

Windows, macOS, Linux

APP

Android, iOS

Firmware

Firmware

Klipper

Specifications

General

Dimensions

584mm × 499mm × 730mm

Build Volume

270mm × 270mm × 270mm

Weight

18.2kg

Printing Properties

Printing Technology

Fused Deposition Modeling

Build Volume

584mm × 499mm × 730mm

Max Toolhead Speed

500mm/s

Max Acceleration Speed

20,000mm/s²

Toolhead

Toolheads Included

4

Max Flow for Hot End

32mm³/s[6]

Nozzle

Stainless Steel

Max Nozzle Temperature

300°C

Nozzle Diameter

0.4mm

Filament Diameter

1.75mm

Part Cooling

Main & Auxiliary Part Cooling Fans

Heated Bed

Build Plate

Flexible Steel Sheet with PEI Surface

Max Heated Bed Temperature

100°C

Supported Filament Type

Basic Material Compatibility

PLA, PETG, TPU, PVA, PCTG

With Optional Top Cover

PLA, PETG, TPU, PVA, PET, ABS, ASA, PA, PC

With Top Cover & Hardened Steel Nozzle

PLA, PETG, TPU, PVA, PET, ABS, ASA, PA, PC, Carbon-fiber-reinforced Polymer, Glass-fiber-reinforced Polymer

Electronics

Touchscreen

3.5-inch 320 × 480 Touchscreen

Data Transmission Methods

Wi-Fi (IEEE802.11b/g/n Standards, 2.4GHz), USB Flash Drive

Storage

26 GB eMMC

Live View Camera

2 Megapixel Built-in Chamber Camera

Max Input Power

1150 W (220-240 V~), 400 W (100-120V~)

Max Input Current

6 A(220-240V~), 4 A(100-120 V~)

Auto-calibration

Heated Bed Leveling

Mesh Bed Leveling

Active Vibration Control

Accelerometer & Input Shaping Calibration(

Automatic Flow Compensation

Pressure Advance Calibration

Automatic Toolhead Offset Calibration

Coordinate Measuring Calibration

Automatic Filament System

Auto-feed

Supported

Backup Mode

Supported

Filament RFID Recognition

Supported

Failure Detection

Air Printing Detection

Supported

Filament Run Out Detection

Supported

Power Loss Recovery

Supported

Anomaly Detection

Toolhead Swap Error Detection

Supported

Build Plate Presence Detection

Supported

Build Plate Obstruction Detection

Supported

Software

Supported Slicer

Snapmaker Orca, Orcaslicer

APP

Snapmaker APP

Firmware

Firmware

Klipper

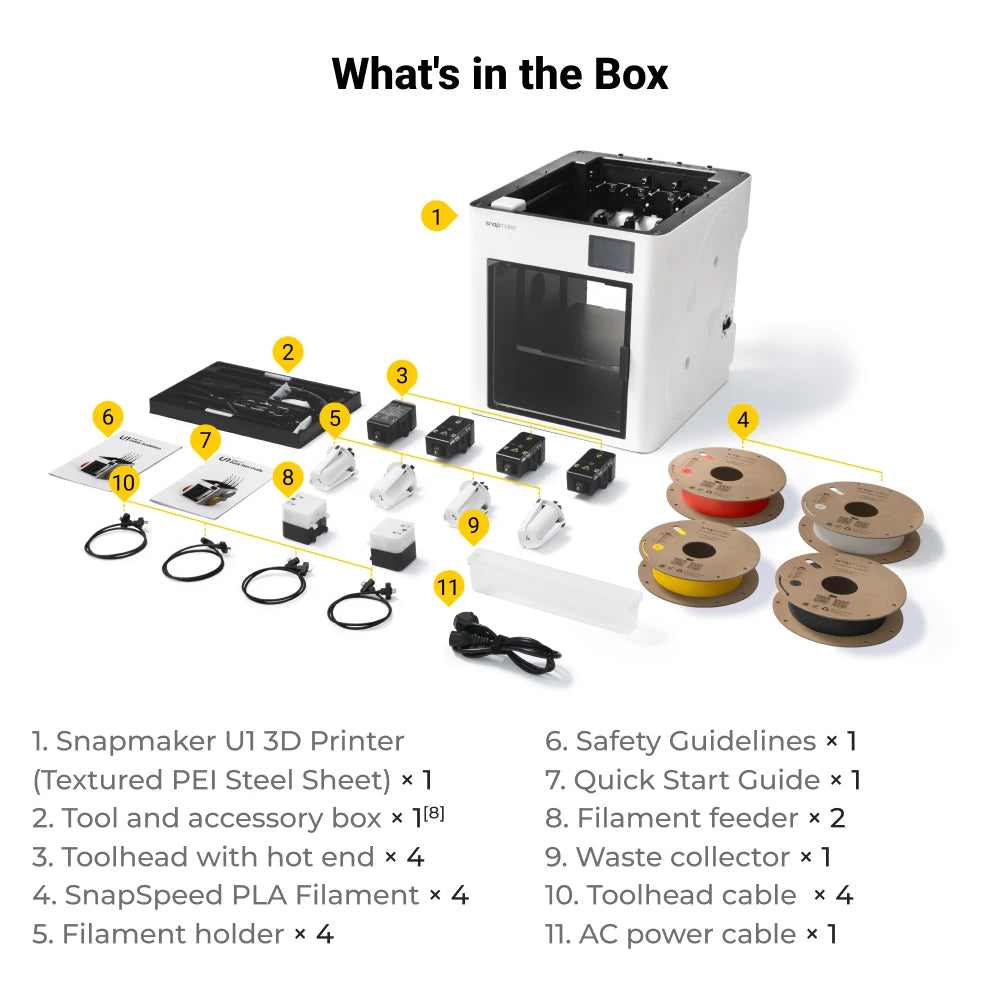

In the Box

- 1. Snapmaker U1 3D Printer (Textured PEI Steel Sheet) × 1

2. Tool and accessory box × 1[8]

3. Toolhead with hot end × 4

4. SnapSpeed PLA Filament × 4

5. Filament holder × 4

- 6. Safety Guidelines × 1

7. Quick Start Guide × 1

8. Filament feeder × 2

9. Waste collector × 1

10. Toolhead cable × 4

11. AC power cable × 1

Notes:

[1] This data was obtained by printing with PLA filament and a 0.4 mm standard-flow nozzle, using a 0.2 mm layer height, 200 mm/s outer wall speed, and 250 mm/s infill speed.

[2] This is a typical result from Snapmaker Lab tests and is for reference only.

[3] Filament usage may vary with model size, color layout, and print settings. In Snapmaker Lab tests under similar conditions, U1 used roughly 17% to 47% of the filament required by other single-head printers for the same multi-color prints.

[4] This data was measured using clean nozzles. Calibrating with an unclean nozzle could lead to less accurate results.

[5] Detection capabilities will be enabled in December 2025 through an OTA firmware update.

[6] This data was obtained using Snapmaker ABS filament, under a printing temperature of 280°C.

Frequently Asked Questions

- Shipment

- Product

- Software

- Firmware

- Warranty

1. When can I receive the Snapmaker U1?

2. What are the Dimensions and Weight of the Snapmaker U1 Shipping Box?

Dimensions: 580mm x 540mm x 500mm

Weight: 26kg (incl. 500g*4 spools of filament)

1. What is the standard nozzle size of the Snapmaker U1?

2. What connection methods does the Snapmaker U1 support?

The Snapmaker U1 supports two connection methods: Wi-Fi and a USB flash drive. You can either connect wirelessly via Wi-Fi to send print jobs or use a USB drive to transfer and start prints directly from the machine.

3. What is the thickness of the heated bed?

The heated bed has an overall thickness of 6.5 mm, consisting of a 1.5 mm base plus 5 mm reinforcing ribs. With this structure, the bed mesh variation is generally controlled within 0.4 mm, ensuring stability and reliable print quality.

4. Does the Snapmaker U1 support third-party filaments?

Yes, the Snapmaker U1 is compatible with third-party filaments, provided they have a diameter of 1.75 mm and meet general material quality standards. However, please note that the RFID recognition feature will not work with third-party filaments.

5.Does the U1 support printing with TPU filaments?

The TPU materials tested so far have a hardness of ≥90A, while those with a hardness of <90A are currently being evaluated. To ensure optimal print quality, we recommend drying the filament before printing.

6.What is the maximum spool size the holder can accommodate?

The spool holder supports spools with an inner diameter of 52–60 mm, a maximum width of 70 mm, and a weight of up to 1 kg. Please ensure your filament spool falls within these limits to avoid feeding issues.

1. What slicing software is supported by Snapmaker U1?

1. What firmware does the Snapmaker U1 use, and is it open source?

1. U1 Warranty Policy

• 1-year warranty for the rest of the world (any country not mentioned above).

For more details, please refer to: U1 Warranty Policy

Shipment| When can I receive the Snapmaker U1?

Shipment| What are the Dimensions and Weight of the Snapmaker U1 Shipping Box?

Dimensions: 580mm x 540mm x 500mm

Weight: 26kg (incl. 500g*4 spools of filament)

Product| What is the standard nozzle size of the Snapmaker U1?

Product| What connection methods does the Snapmaker U1 support?

The Snapmaker U1 supports two connection methods: Wi-Fi and a USB flash drive. You can either connect wirelessly via Wi-Fi to send print jobs or use a USB drive to transfer and start prints directly from the machine.

Product| What is the thickness of the heated bed?

The heated bed has an overall thickness of 6.5 mm, consisting of a 1.5 mm base plus 5 mm reinforcing ribs. With this structure, the bed mesh variation is generally controlled within 0.4 mm, ensuring stability and reliable print quality.

Product| Does the Snapmaker U1 support third-party filaments?

Yes, the Snapmaker U1 is compatible with third-party filaments, provided they have a diameter of 1.75 mm and meet general material quality standards. However, please note that the RFID recognition feature will not work with third-party filaments.

Product| Does the U1 support printing with TPU filaments?

The TPU materials tested so far have a hardness of ≥90A, while those with a hardness of <90A are currently being evaluated. To ensure optimal print quality, we recommend drying the filament before printing.

Product| What is the maximum spool size the holder can accommodate?

The spool holder supports spools with an inner diameter of 52–60 mm, a maximum width of 70 mm, and a weight of up to 1 kg. Please ensure your filament spool falls within these limits to avoid feeding issues.

Software| What slicing software is supported by Snapmaker U1?

Firmware | What firmware does the Snapmaker U1 use, and is it open source?

Warranty| U1 Warranty Policy

• 1-year warranty for the rest of the world (any country not mentioned above).

For more details, please refer to: U1 Warranty Policy