This is addons

Snapmaker 2.0 Dual Extrusion 3D Printing Module

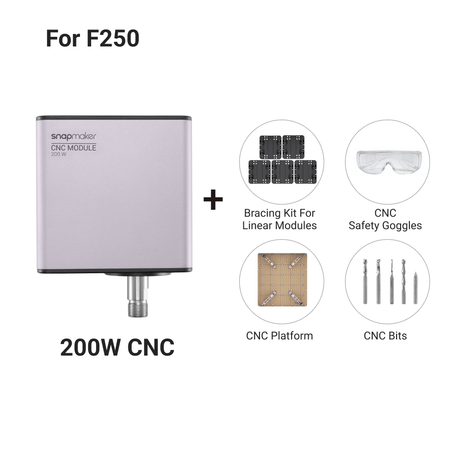

From €349,00 EUR€699,00Unit price /UnavailableIn stockSnapmaker 200W CNC Module Bundle (VAT Incl.)

From €199,00 EUR€329,00Unit price /UnavailableIn stockSnapmaker Rotary Module (Harmonic Drive Version) (VAT Incl.)

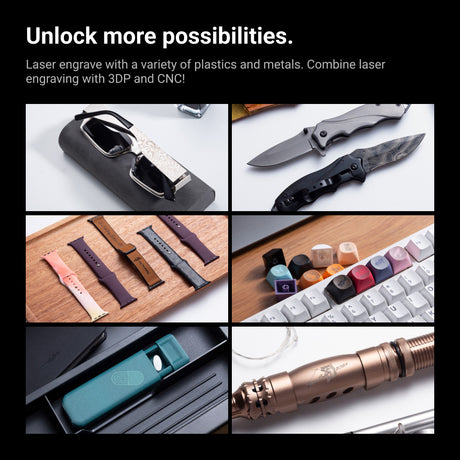

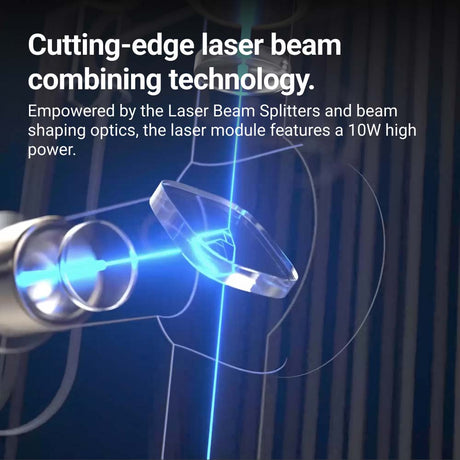

From €349,00 EUR€699,00Unit price /UnavailableIn stockSnapmaker 10W High Power Laser Module (VAT Incl.)

From €199,00 EUR€519,00Unit price /UnavailableIn stockSnapmaker 2.0 Emergency Stop Button (VAT Incl.)

€55,20 EUR€69,00Unit price /Unavailable

FAQs

1. How are Snapmaker Artisan and Snapmaker 2.0 compatible with other modules and addons?

Please refer to the compatibility table below:

2. Is the Quick Swap Kit compatible with the A150?

No, the kit is not compatible with the A150 due to the fixed structure of its platform and also the reason that the platform switching time for the A150 is much shorter than that of the A250 and A350.

3. Can I upgrage J1/J1s with other modules?

No, the J1/J1S is a standalone IDEX 3D printer and does not support upgrades with additional modules.

4. Can I use multiple modules at once on my Snapmaker?

No, only one module can be used at a time. However, you can easily swap modules with our Quick Swap Kit, allowing you to switch between functions for maximum creative flexibility.

5. When is the Snapmaker CAN Hub needed?

The Can Hub is only necessary if you want to use the Air Purifier and Emergency Stop Button on Snapmaker 2.0 simultaneously. If you want to purchase Artisan, you do not need to buy the Can Hub.

6. Which models can Snapmaker air purifier be used with?

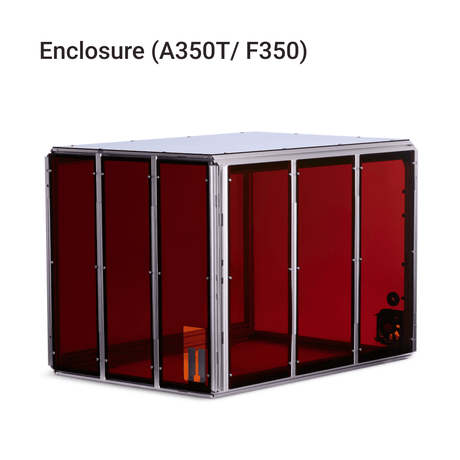

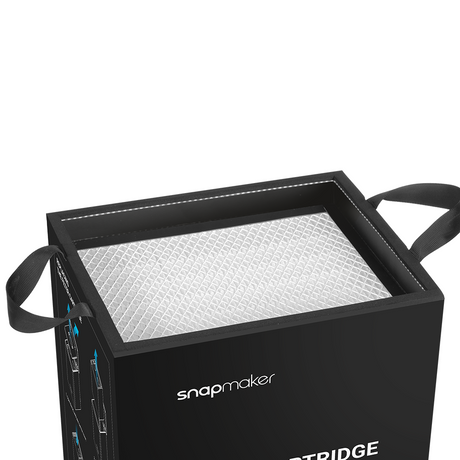

Our Air Purifier is compatible with our Snapmaker 2.0, Snapmaker Artisan and Snapmaker Ray. Please noted that it must be used together with the Enclosure.

7. Is the Snapmaker rotary module suitable for laser engraving?

Yes, the Rotary Module works with the laser toolhead, allowing you to engrave cylindrical items such as glassware, leather bracelets, or bamboo objects.

FAQs

1. How are Snapmaker Artisan and Snapmaker 2.0 compatible with other modules and addons?

Please refer to the compatibility table below:

2. Is the Quick Swap Kit compatible with the A150?

No, the kit is not compatible with the A150 due to the fixed structure of its platform and also the reason that the platform switching time for the A150 is much shorter than that of the A250 and A350.

3. Can I upgrage J1/J1s with other modules?

No, the J1/J1S is a standalone IDEX 3D printer and does not support upgrades with additional modules.

4. Can I use multiple modules at once on my Snapmaker?

No, only one module can be used at a time. However, you can easily swap modules with our Quick Swap Kit, allowing you to switch between functions for maximum creative flexibility.

5. When is the Snapmaker CAN Hub needed?

The Can Hub is only necessary if you want to use the Air Purifier and Emergency Stop Button on Snapmaker 2.0 simultaneously. If you want to purchase Artisan, you do not need to buy the Can Hub.

6. Which models can Snapmaker air purifier be used with?

Our Air Purifier is compatible with our Snapmaker 2.0, Snapmaker Artisan and Snapmaker Ray. Please noted that it must be used together with the Enclosure.

7. Is the Snapmaker rotary module suitable for laser engraving?

Yes, the Rotary Module works with the laser toolhead, allowing you to engrave cylindrical items such as glassware, leather bracelets, or bamboo objects.