}

}

}

}

}

}

Up to €50 off

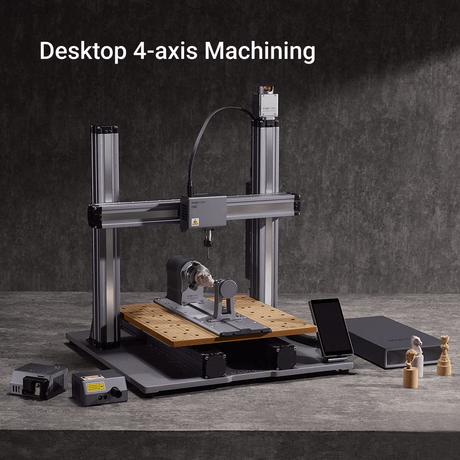

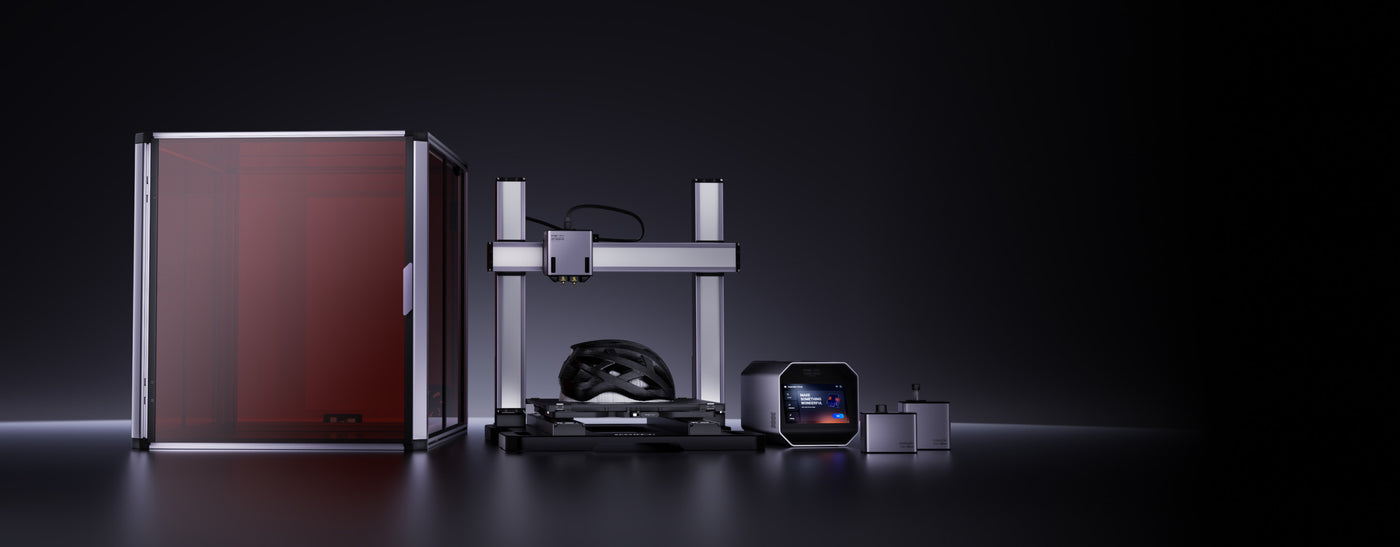

SNAPMAKER 200W CNC MODULE BUNDLE

4× faster CNC machining.

For 2.0 A/AT Models €279 €329

-

Free shipping

On all orders over €99

-

Warranty Protection

2-year warranty

-

Easy Return & Refund

14-day return and refund service

-

Secure Payments

Credit cards, PayPal, bank wires, Klarna

ALL SERIES

Modules

View all

Snapmaker's Signature Modular Design

Come explore a broader world of multiplied possibilities with modules.

-

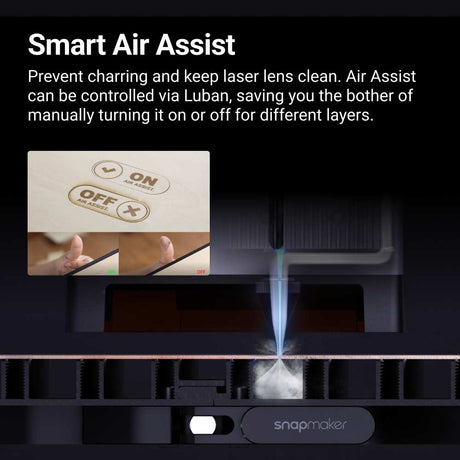

Snapmaker 20W & 40W Laser Module with Air Assist (VAT Incl.)

From €589,00 EUR€639,00Unit price /UnavailableIn stock -

Snapmaker Rotary Module (Harmonic Drive Version) (VAT Incl.)

From €459,00 EUR€639,00Unit price /UnavailableIn stock -

Snapmaker 2.0 Dual Extrusion 3D Printing Module (VAT Incl.)

€499,00 EUR€699,00Unit price /UnavailableIn stock -

-

-

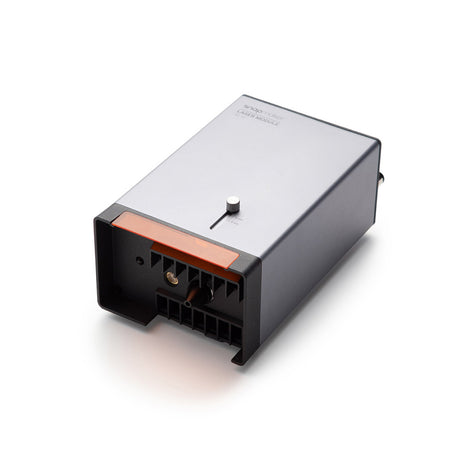

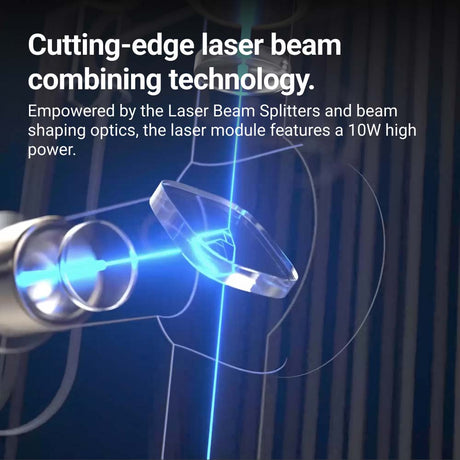

Snapmaker 10W High Power Laser Module (VAT Incl.)

From €349,00 EUR€519,00Unit price /UnavailableIn stock -

Snapmaker 200W CNC Module Bundle (VAT Incl.)

From €279,00 EUR€329,00Unit price /UnavailablePreorder -

CUSTOMER REVIEWS