The new generation 3-in-1 3D printer, like the Snapmaker 2.0, is designed to be user-friendly and easy to operate for both beginners and experienced users.

One of the most user-friendly features of the new generation 3-in-1 3D printer is its touchscreen interface, which provides a simple and intuitive way to control the machine. The touch screen allows users to access all the functions and settings of the printer, including the print bed leveling system, filament loading and unloading, speed adjusting, and project management.

The new generation 3-in-1 3D printer also comes with user-friendly software called Snapmaker Luban, which allows users to create 3D models, slice them, and prepare them for printing. The software has a simple and intuitive interface that makes it easy for users to design and print their own creations in high precision.

Additionally, the new generation 3-in-1 3D printer has an auto-leveling system that helps ensure that the print bed is level and the first layer of the print adheres properly. This feature reduces the need for manual leveling and makes the printing process more reliable and consistent.

Overall, the new generation 3-in-1 3D printer is designed with the user in mind, with features and tools that make it easy to use and produce high-quality prints.

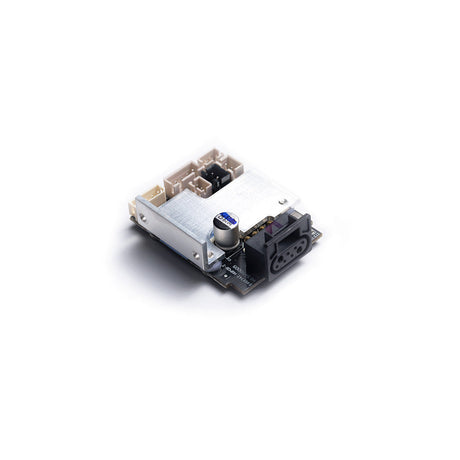

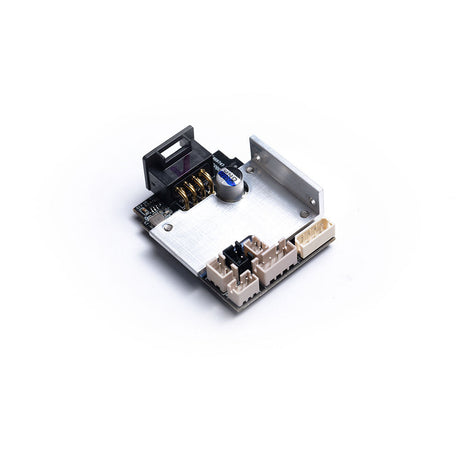

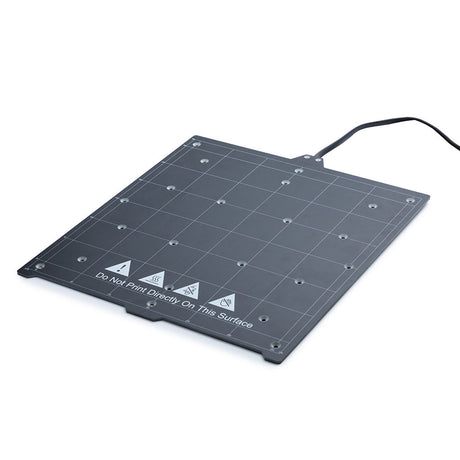

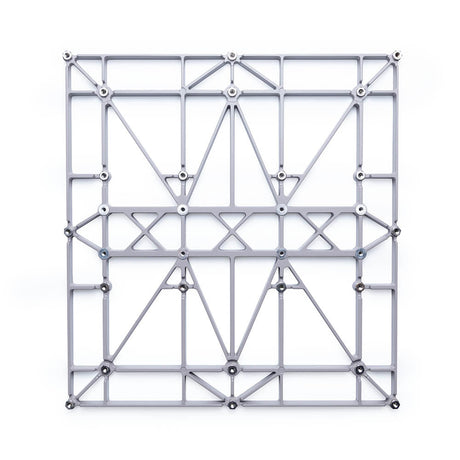

![[REPLACEMENT] DOUBLE-SIDED PEI GLASS PLATE FOR SNAPMAKER J1/J1S](http://eu.snapmaker.com/cdn/shop/products/J1__1_1000_1000_b5408d1b-36b8-4214-a7e8-48cd1596178a.png?v=1667914597&width=460)

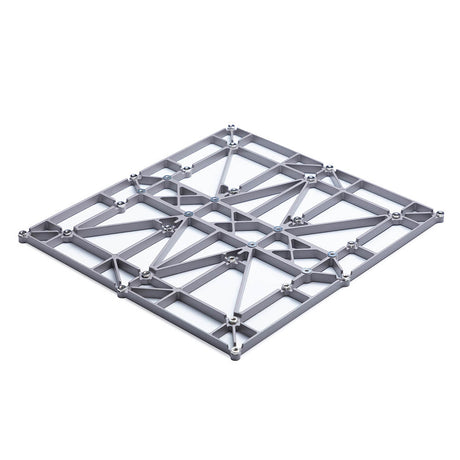

![[REPLACEMENT] DOUBLE-SIDED PEI GLASS PLATE FOR SNAPMAKER J1/J1S](http://eu.snapmaker.com/cdn/shop/products/J1__2_1000_1000_356d2fa6-31d4-4e94-b6a1-bc6419b48704.png?v=1667914597&width=460)